H2 refuelling station technology

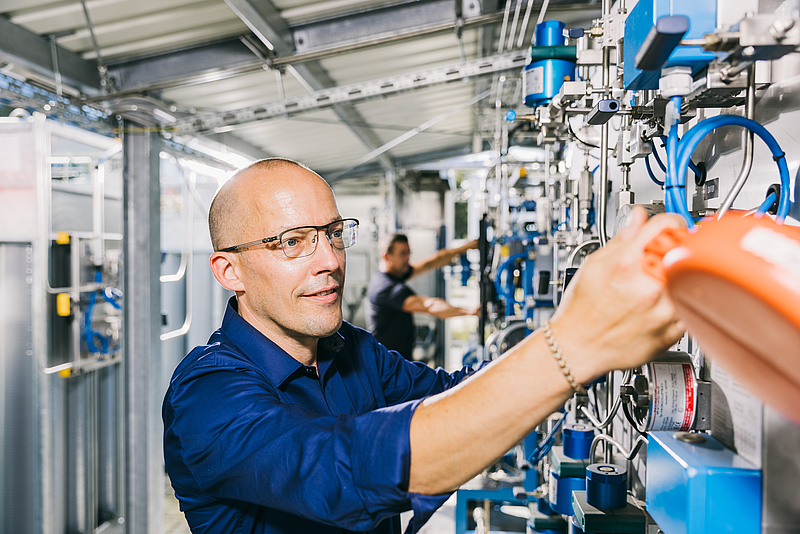

For the market introduction of fuel cell-based mobility, efficient and cost-effective refuelling technologies for passenger cars, commercial vehicles, trucks, buses, trains, etc. must be developed. The ZBT’s Hydrogen Infrastructure department focuses on the targeted development and qualification of components and concepts for hydrogen refuelling stations (HRS). One focus is on refuelling protocols.

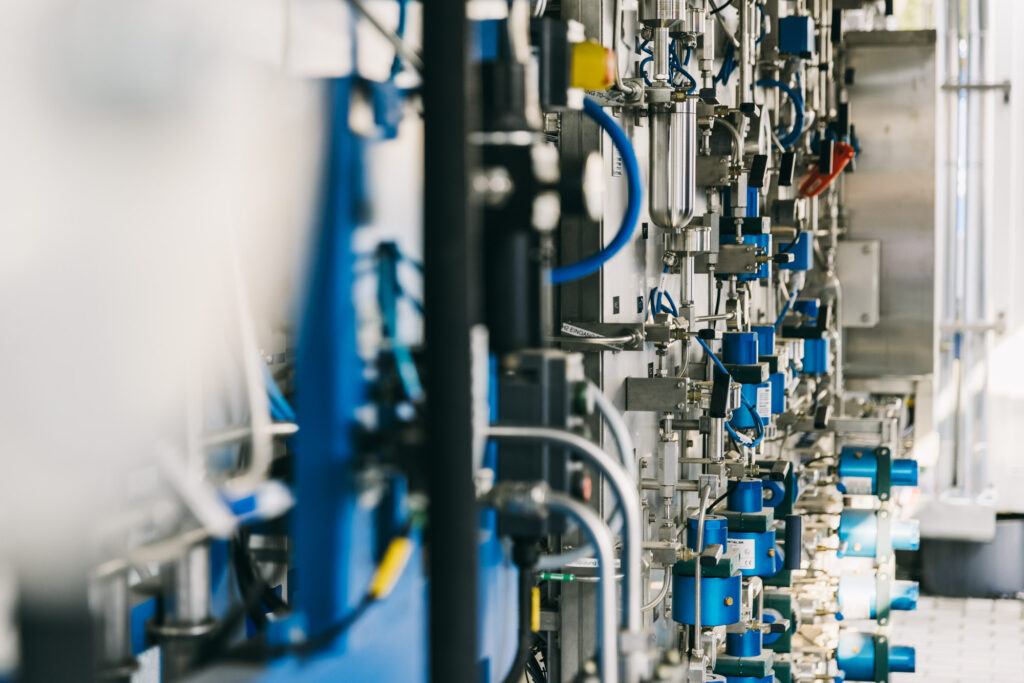

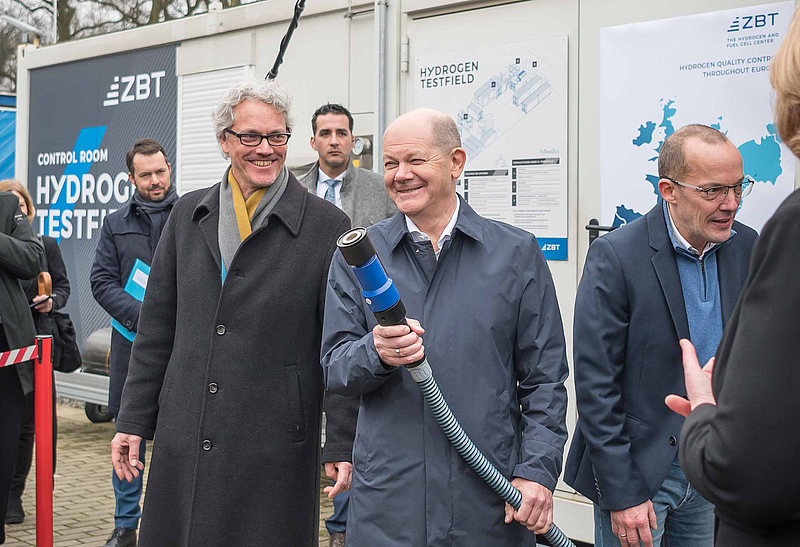

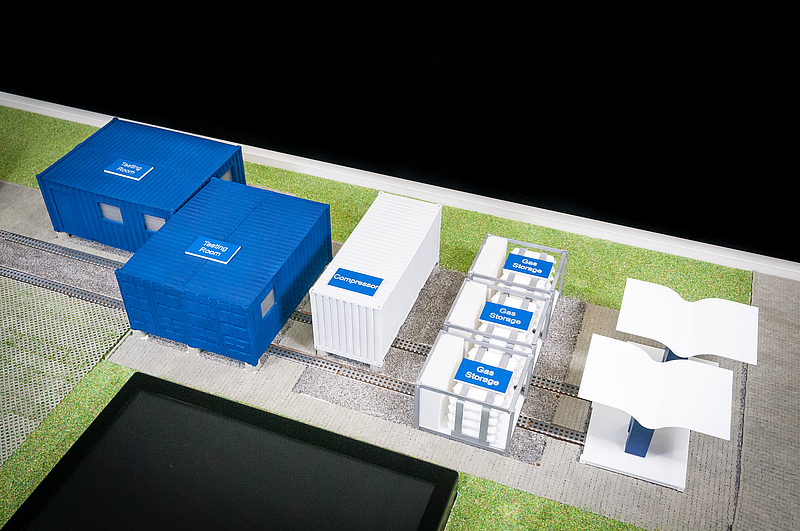

All activities at our hydrogen test filling station are based on a systemic approach, i.e. the effects on the overall system are always taken into account. Consequently, components and concepts are also developed and qualified in the related areas of distribution and tank systems. Our hydrogen test filling station is part of the hydrogen test field and enables realistic operation. As it is not a commercial filling station, we can develop and test components and concepts undisturbed under real conditions.

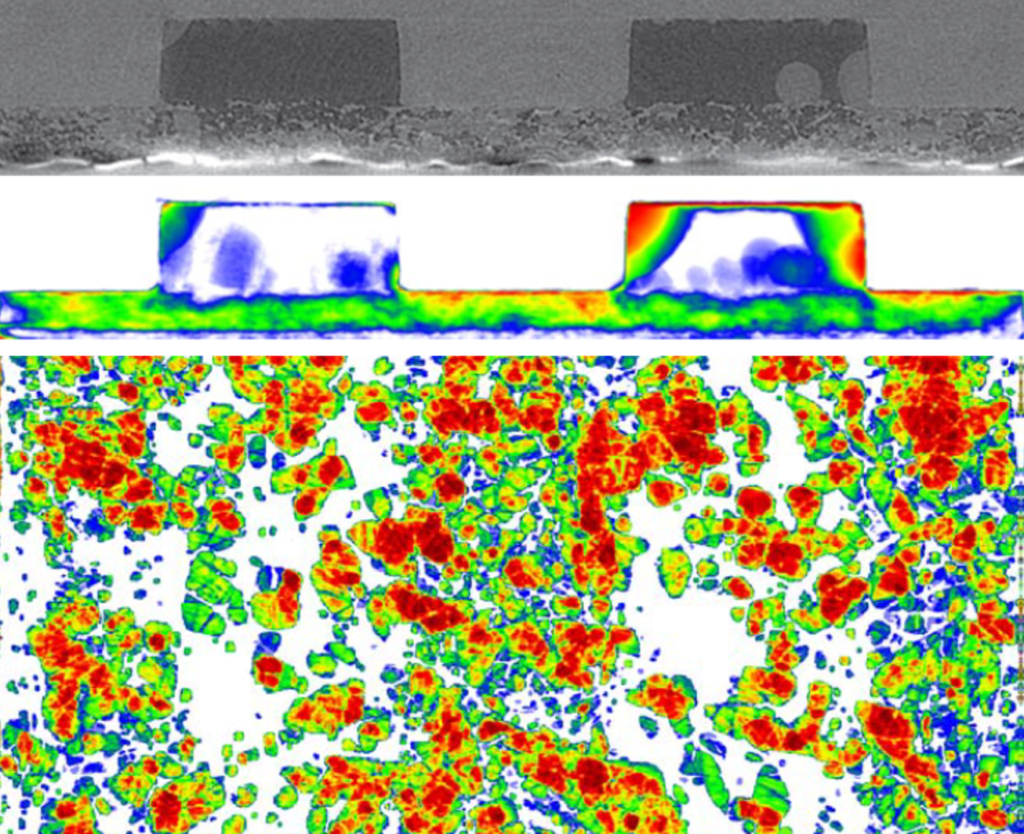

The R&D work is supported by modelling and simulation of filling systems, HRS, HRS components and refuelling. Based on these models, new HRS can be designed in a load-dependent, optimised manner and existing systems can be optimised in terms of their operation.

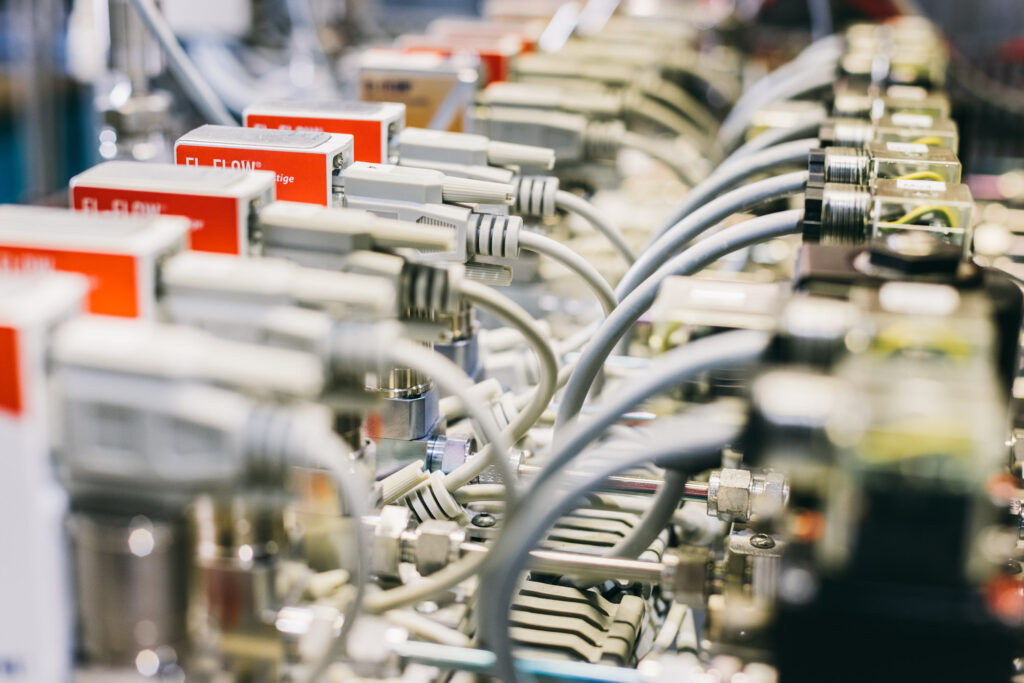

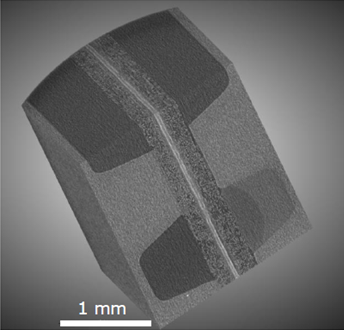

As part of numerous national and international R&D projects and customer orders, heavy-duty tank systems and filling station components have been investigated and the development of HD refuelling protocols has been supported by tests on fully instrumented individual storage tanks with 350, 500 and 700 bar.