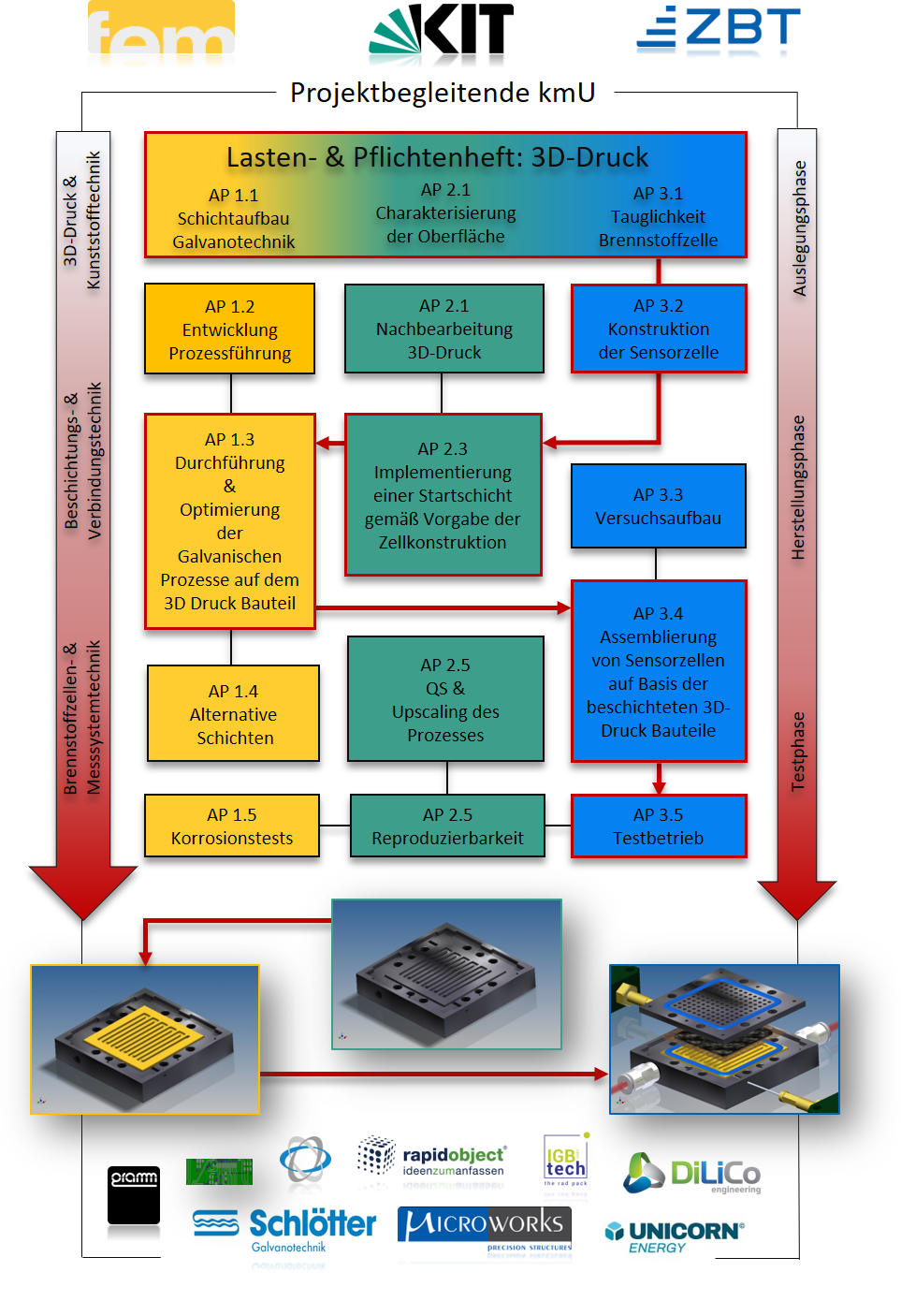

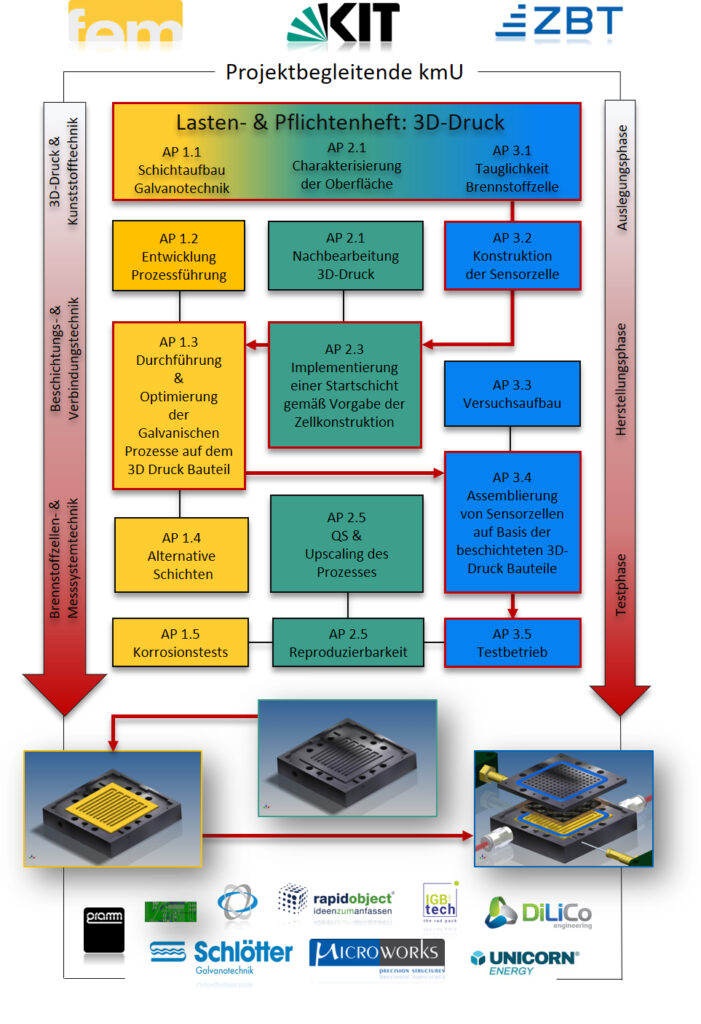

When used as sensors, such cells support research, development and quality assurance under real operating conditions. As consumables, they must be flexible in terms of shape and quantity, inexpensive to manufacture and easy to replace and handle. Currently, there are no commercially available fuel cells that are functionally suitable for such sensor tasks. Production is not a lucrative business for large companies due to high material and development costs.

However, Germany has a robust infrastructure of small and medium-sized companies that can serve highly diversified markets thanks to their technological leadership. In the field of sensor cells, however, new manufacturing processes are needed that are flexible in terms of form factors and quantities. Only then will it be possible to develop and manufacture such cells under realistic cost scenarios for the widest possible range of applications.