MetalFoil-PTL

Development of structured metal foils as novel porous transport layers for water electrolysis (MetalFoil-PTL)

Further development of porous transport layers in PEM electrolysis

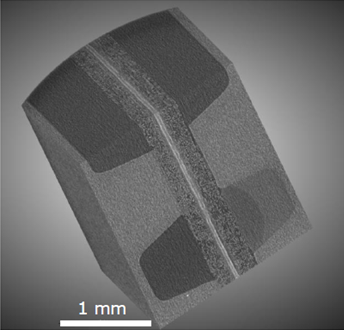

PEM electrolysis is an environmentally friendly way of producing hydrogen from water and renewable electricity. This technology has already been demonstrated on an industrial scale, but is currently still associated with high operating and acquisition costs. ZBT and Ruhr University Bochum are addressing both of these issues. Together, they want to optimise the porous transport layer (PTL), a central component of PEMWE.

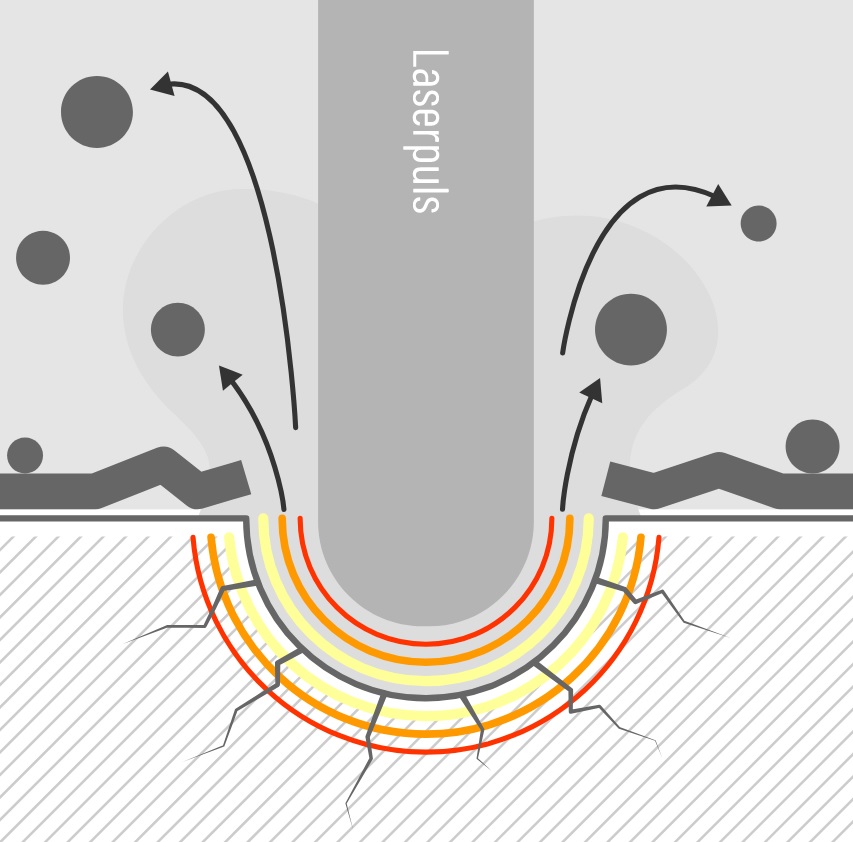

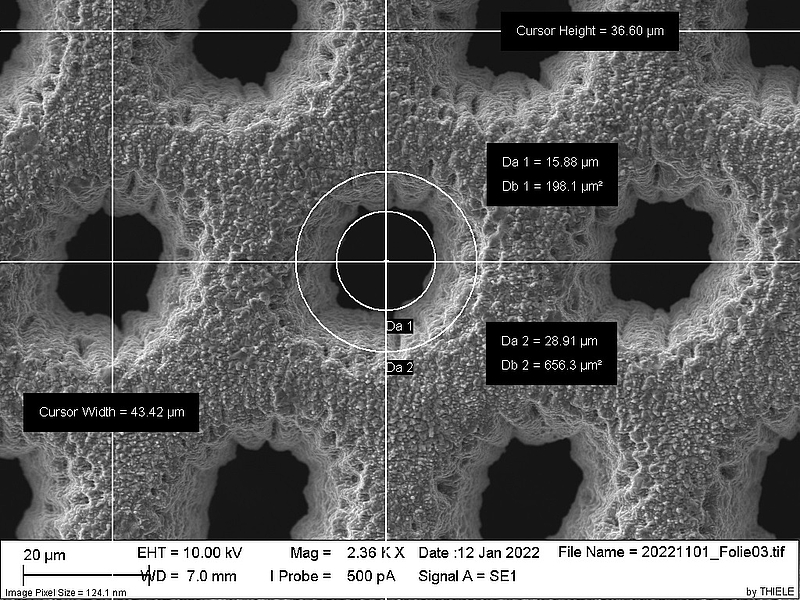

To this end, PTLs are being manufactured from commercially available titanium foil using a novel manufacturing process developed at the Chair of Laser Application Technology (LAT) at Ruhr University. This process is based on ultra-short pulse laser technology (UKP-LT) and makes it possible to perforate the foil in the same processing step and to design the remaining web surfaces down to the low µm range with high precision. This means that the manufacturing technology is very well suited to the characteristic dimensions of PTL and expands the parameter space available for PTL design. This is the starting point for reducing operating costs through efficiency improvements. This PTL approach also addresses manufacturing costs, as the films used are relatively inexpensive and potentially suitable for large-scale roll-to-roll production.

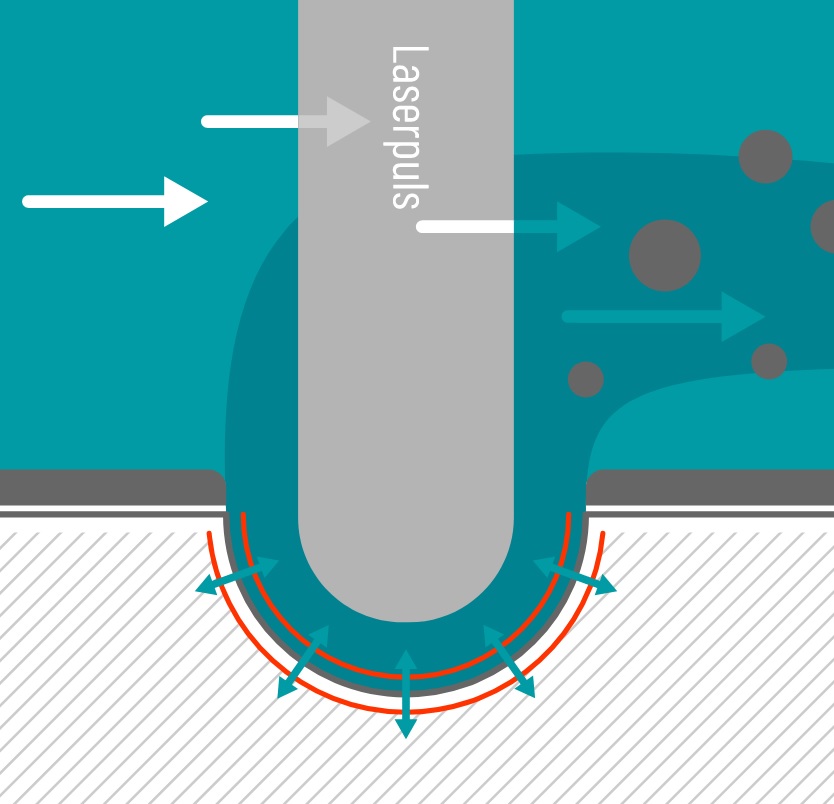

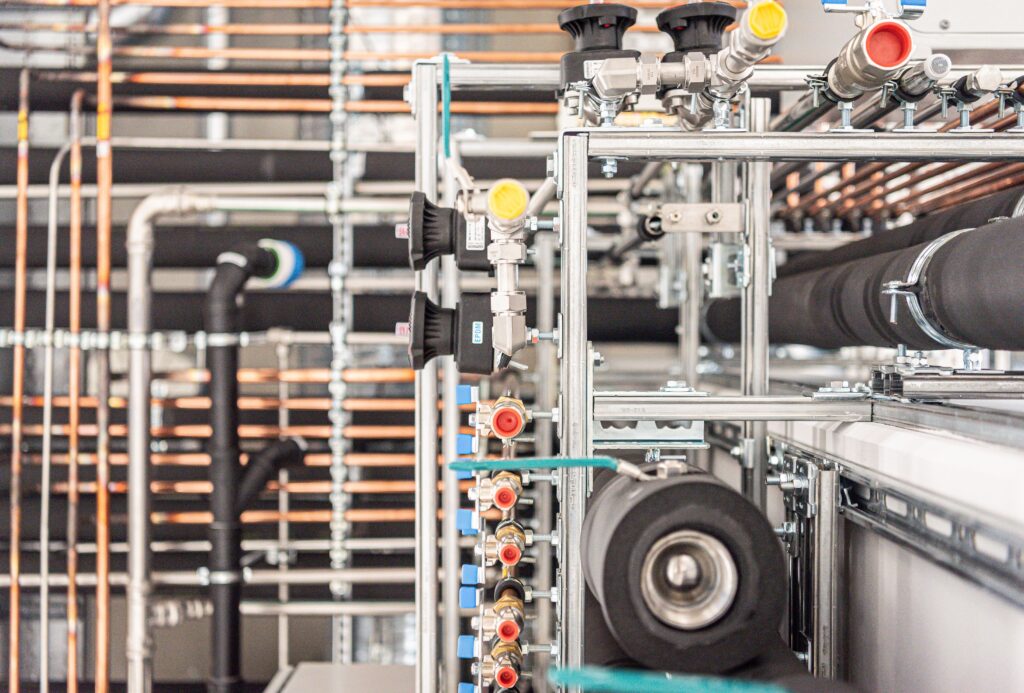

Liquid-flow processing chamber

A special feature of the UPK-LT manufacturing process, which makes it possible to laser PTLs in the first place, is the liquid-flowing processing chamber. The liquid ensures much more effective heat dissipation compared to UKP in a gas atmosphere, thus reducing oxidation of the titanium foil. This makes the process particularly suitable for use in electrolysis.

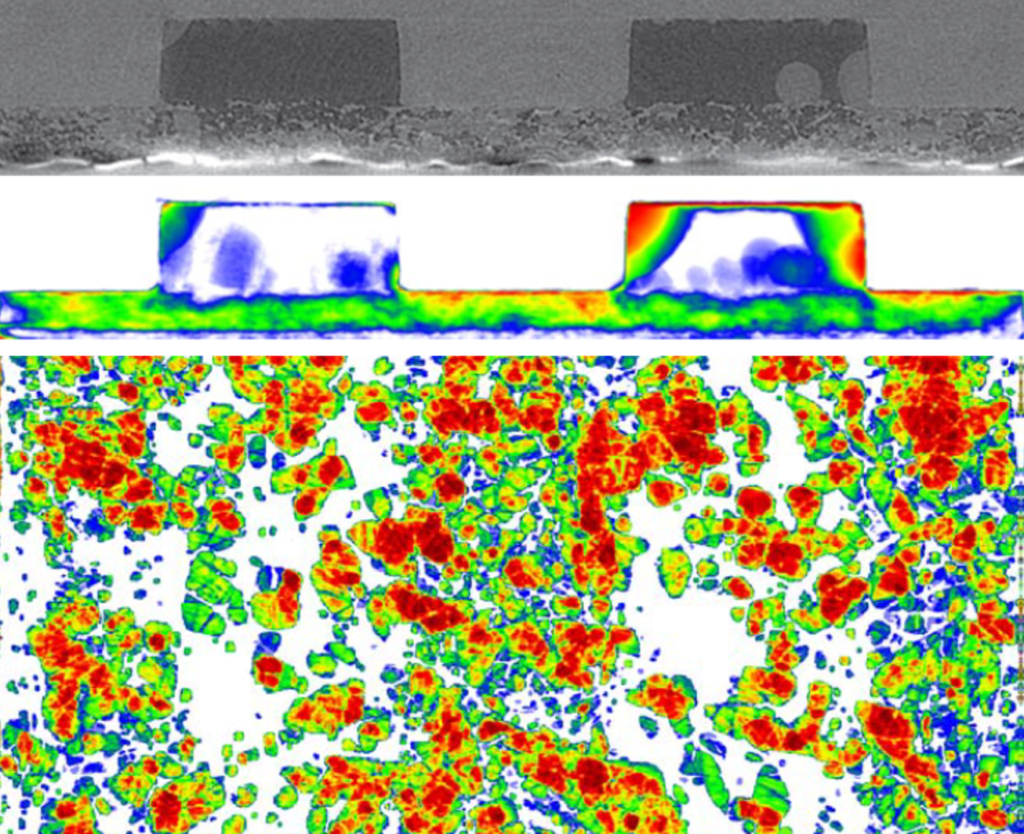

At LAT, the focus is on optimising the laser parameters for the best possible manufacturing quality and speed, as well as a feasibility study on the scalability of production. The scientific goal of ZBT is to explore the newly acquired parameter space with regard to efficiency optimisation and a deeper understanding of PTL morphology.

Initial measurement results have already confirmed functionality and are in line with reference products.

Project partners

Ruhr University Bochum

- Project duration: 01.09.2021 – 31.08.2024

- Funding code: IGF-21971 N