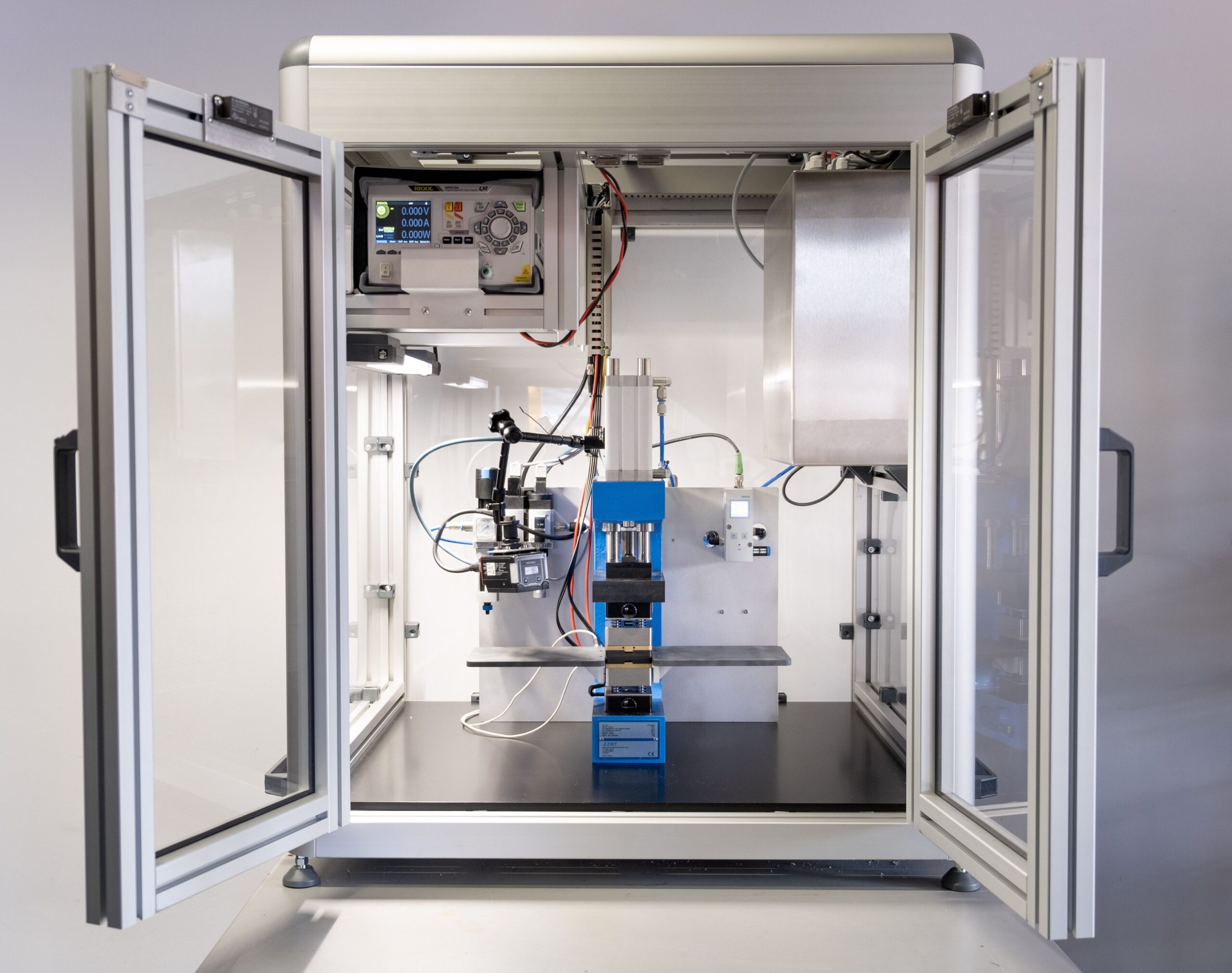

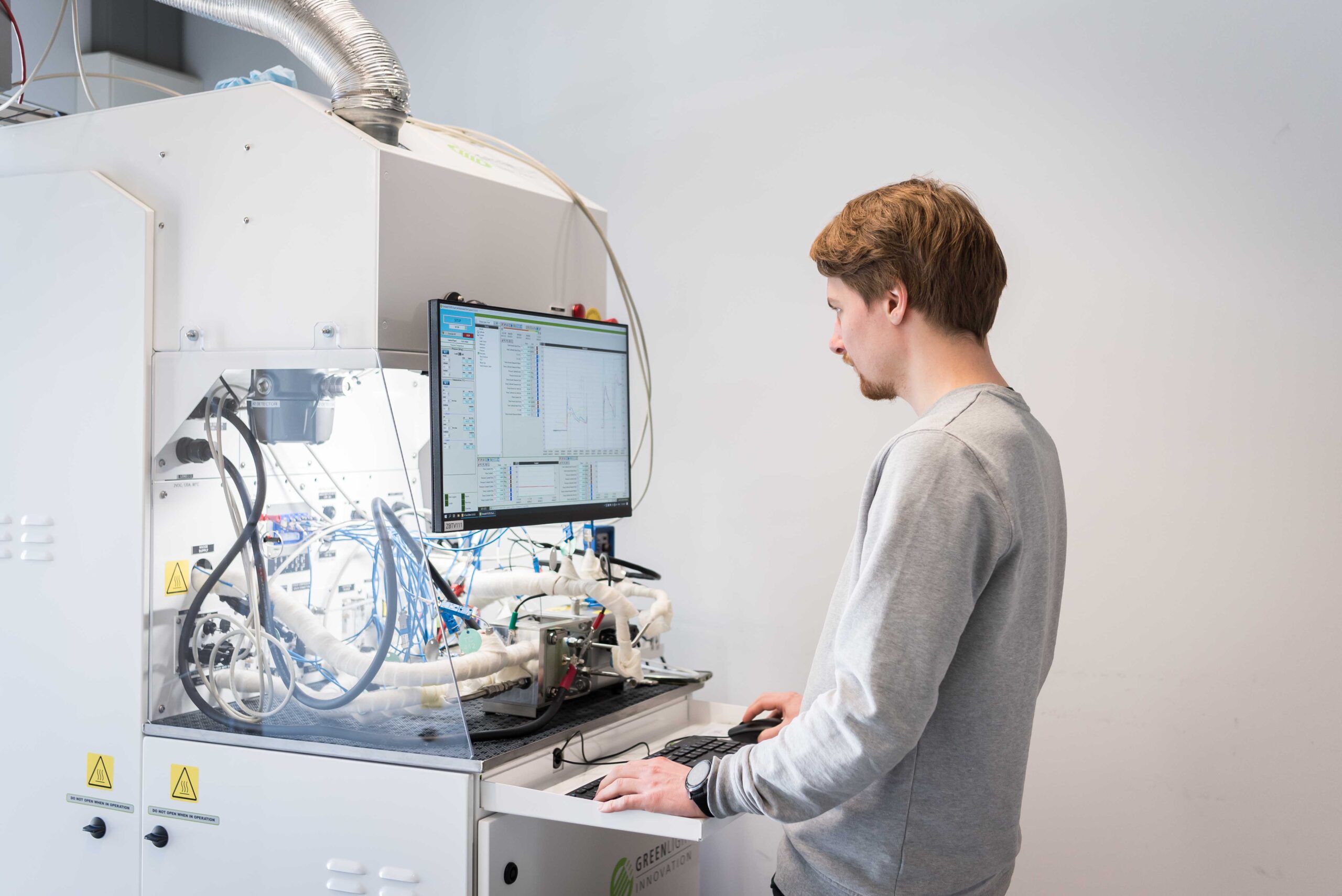

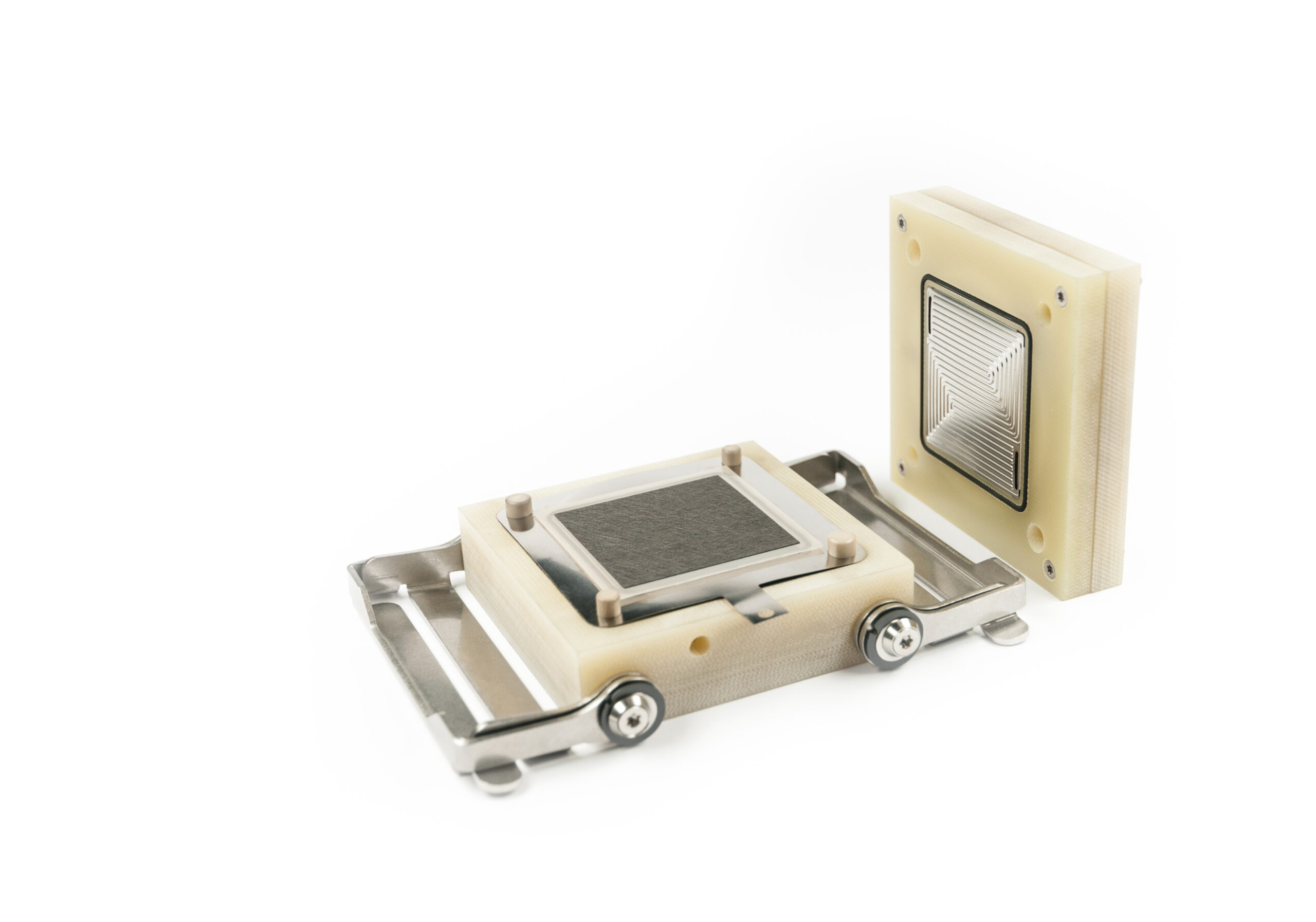

Measurement and Testing Procedures

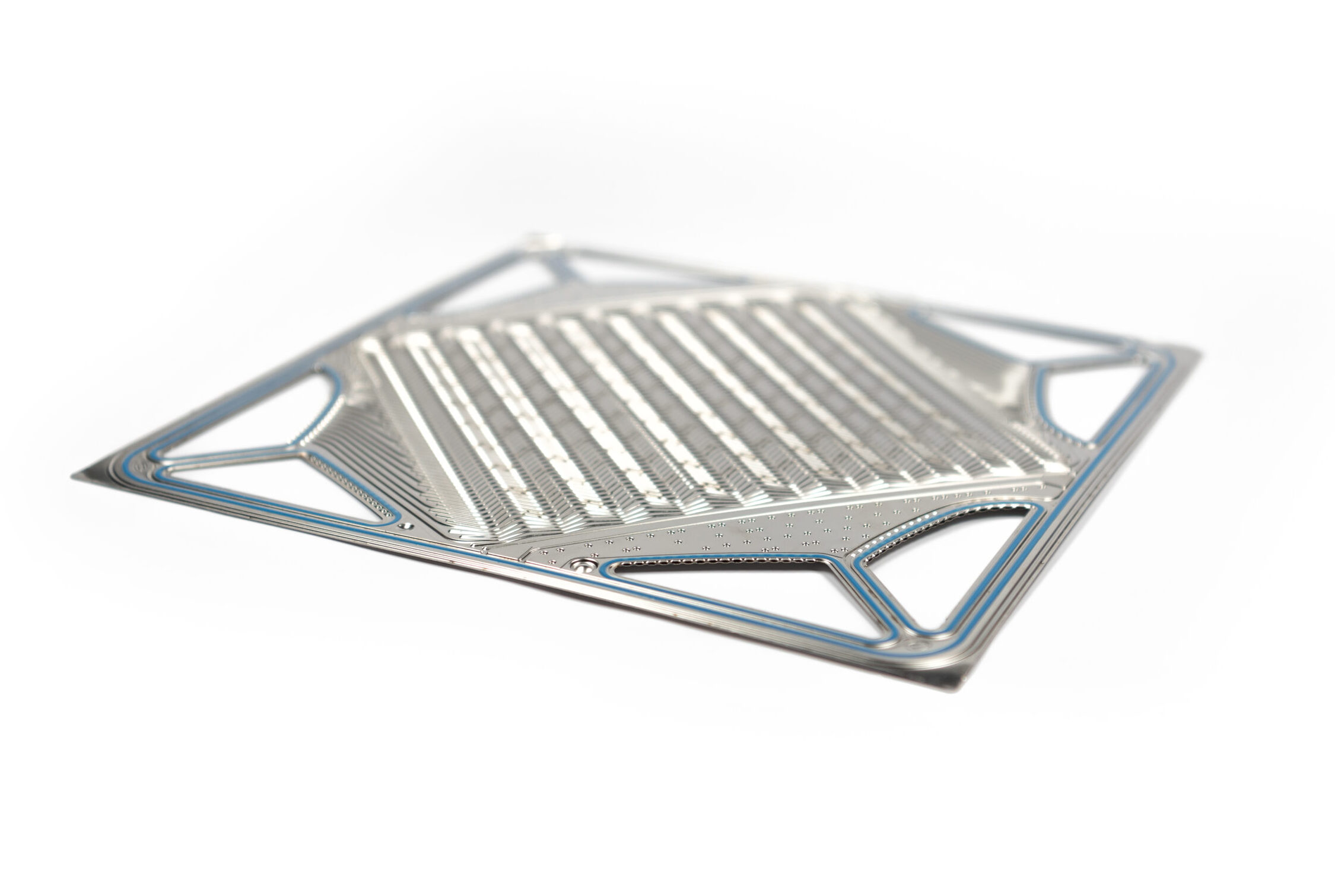

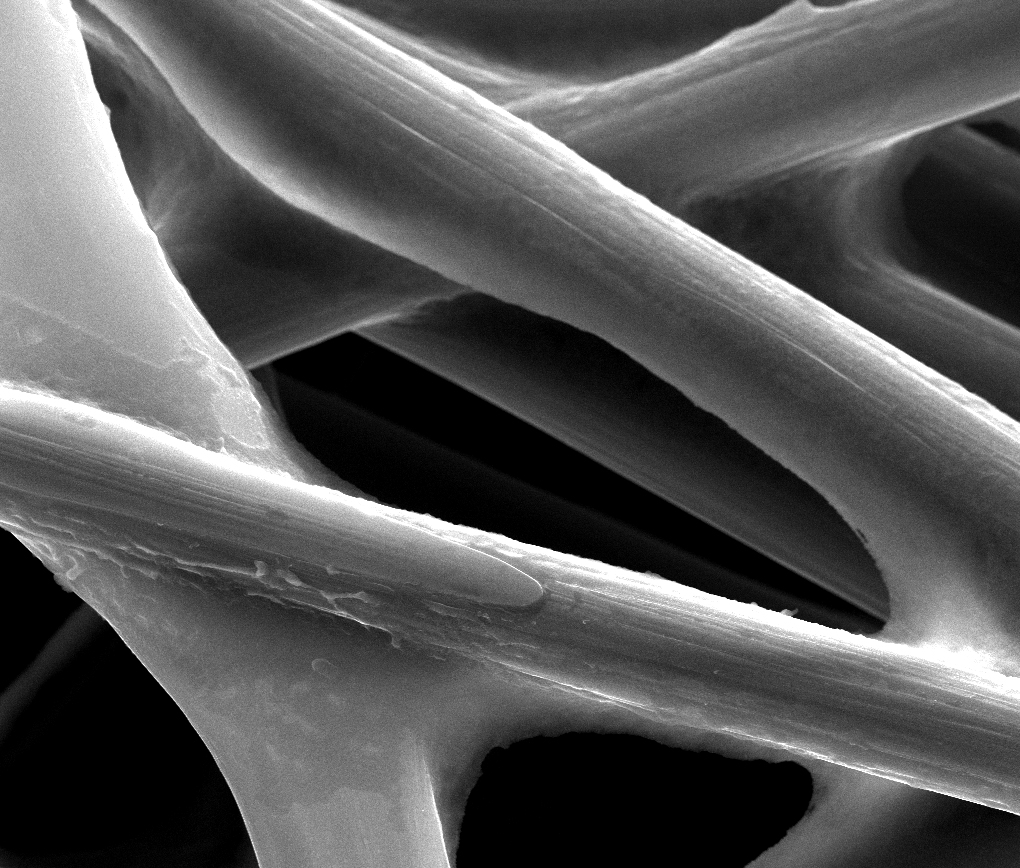

Material and system testing for fuel cell and electrolysis technology

ZBT offers a comprehensive portfolio of measurement and testing procedures for components and systems in hydrogen and fuel cell technology. The focus is on analytical procedures for material characterisation, electrochemical testing methods, quality testing during development and investigations into ageing behaviour. The services support research, product development and industrial quality assurance.