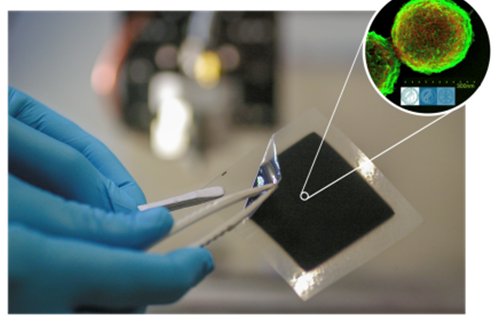

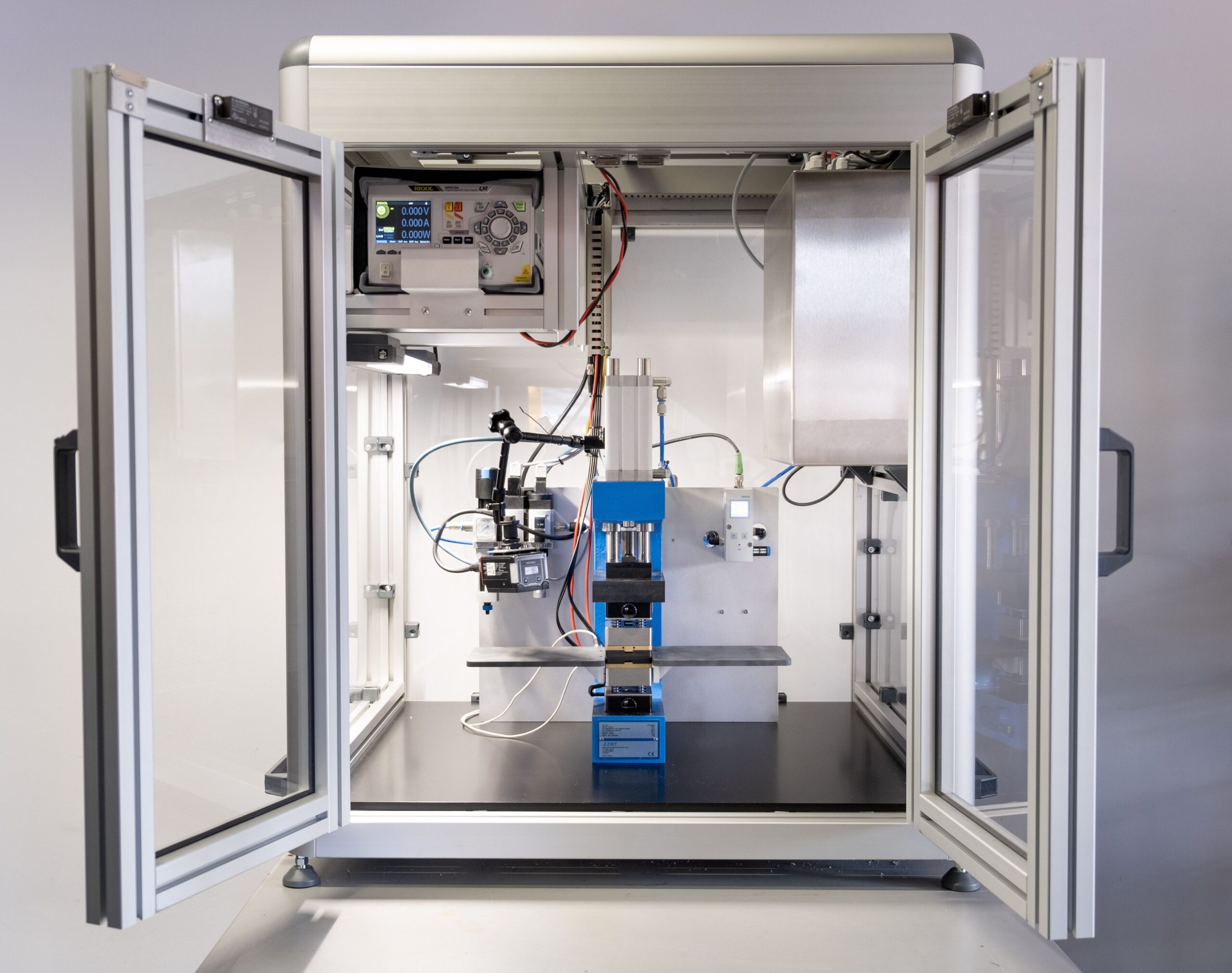

The development and manufacture of tailor-made catalyst and functional layers for fuel cells requires precisely formulated dispersion production. Active materials, binders and solvents are mixed in a targeted manner to produce a homogeneous suspension with optimum properties for the coating process. The choice of components has a significant influence on the electrochemical activity, mechanical stability and durability of the layers.

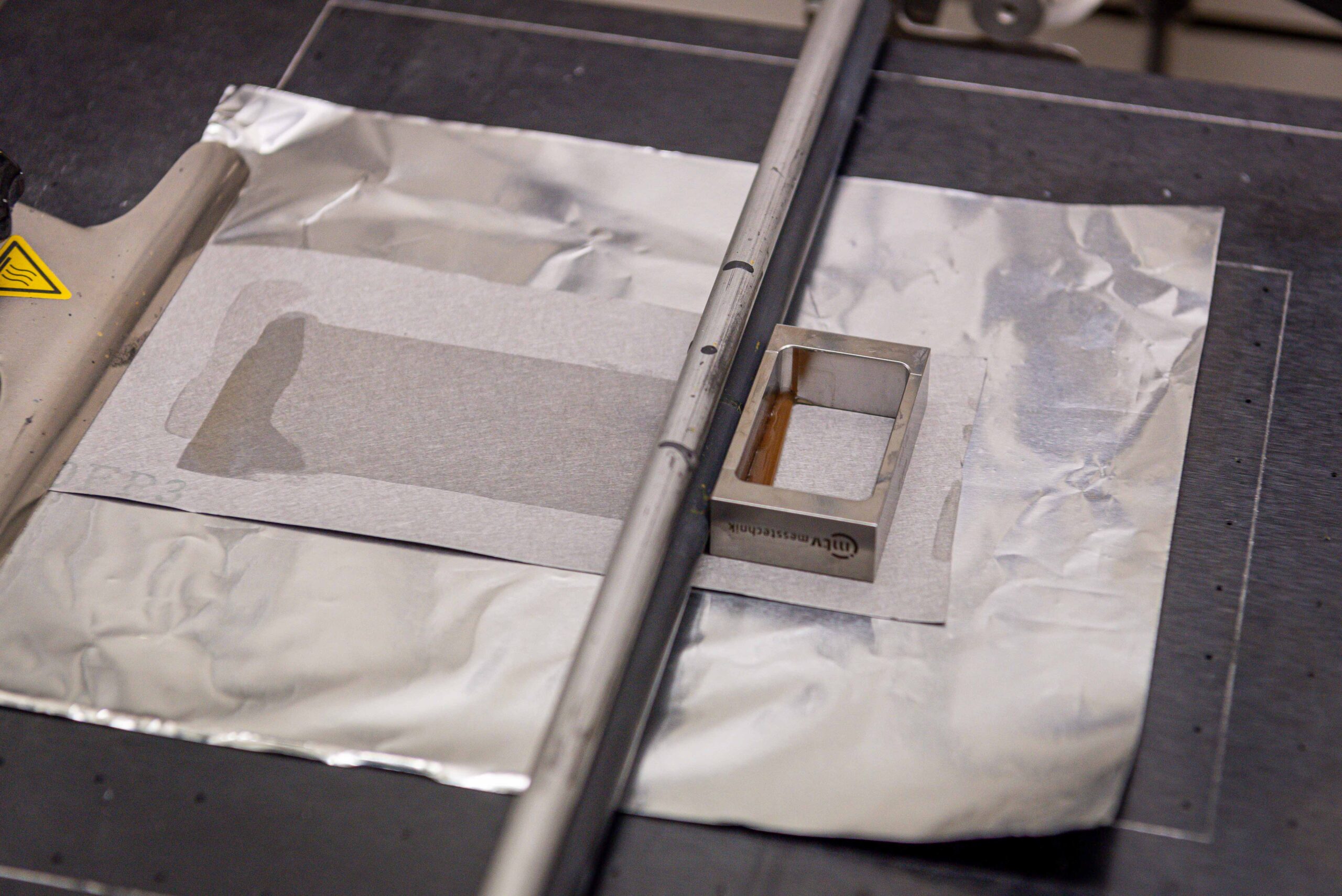

A key aspect is the adaptation of the dispersion to the coating process. Different application techniques such as slot die, spray or squeegee coating require specific viscosities and particle size distributions to ensure uniform layer formation and optimum adhesion.

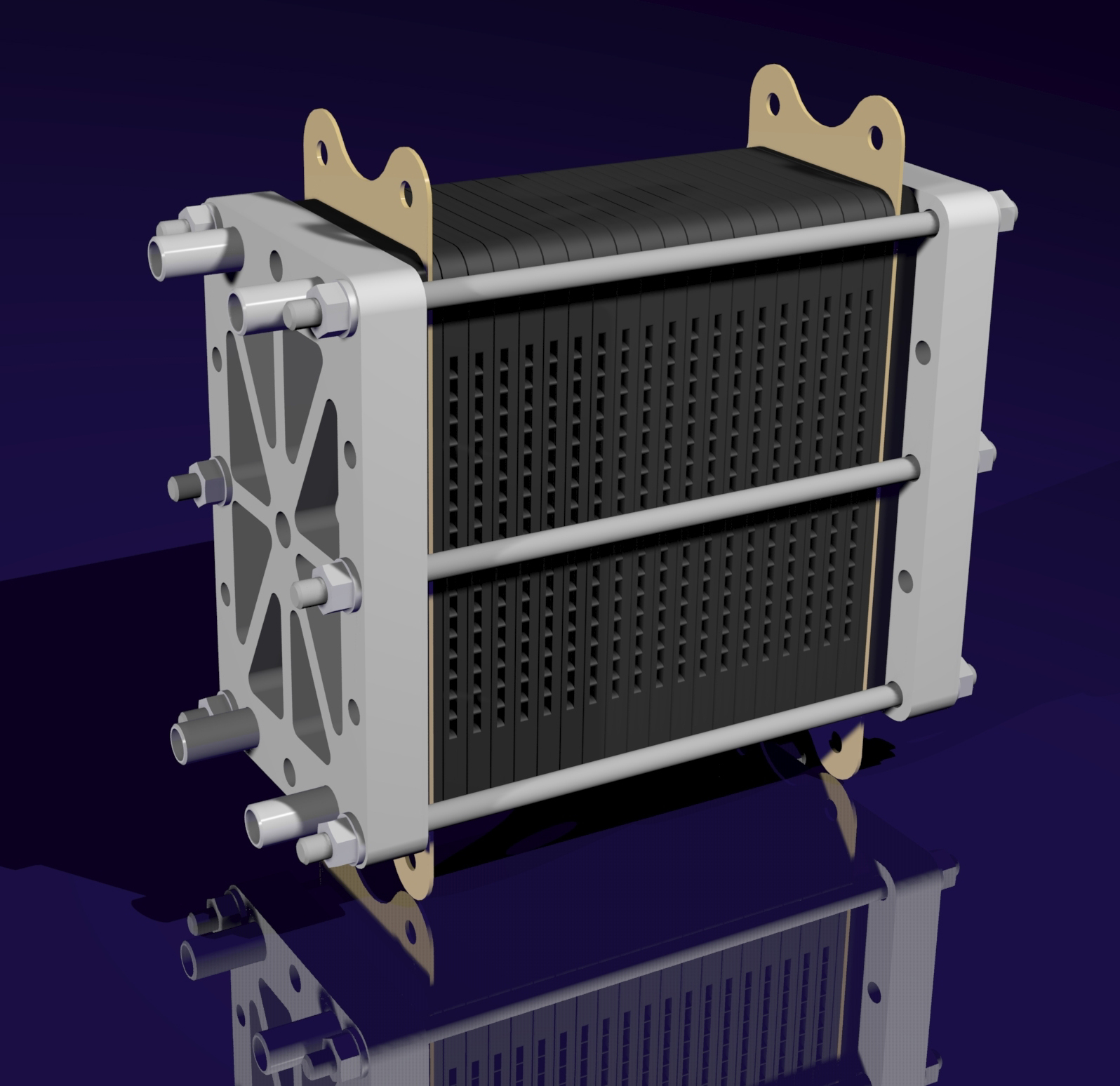

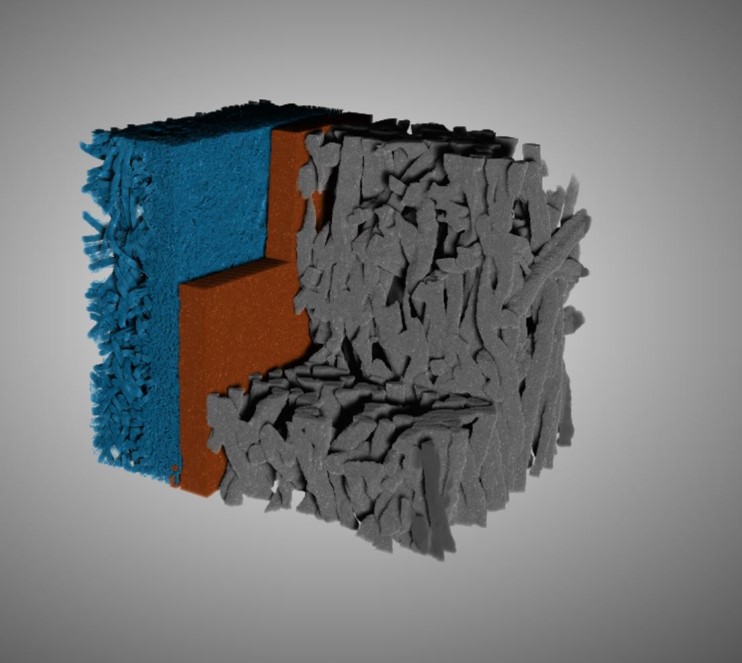

In addition, the integration of functional layers plays an important role. Reinforcement layers increase mechanical stability, while recombination layers contribute specifically to reducing gas transmission. The combination of different material layers enables targeted performance enhancement and adaptation to different operating conditions.

The close integration of material development, process technology and quality assurance enables the realisation of optimised coating systems that are suitable for industrial applications as well as for scaling up to mass production.

![Spritzgussmaschine wird von [...] gesteuert.](https://zbt.de/app/uploads/2024/10/Spritzgusstechnik-ZBT_Duisburg_11.jpg)