Theoretical work and studies cover topics such as hydrogen distribution concepts for connecting industries and mobility, analyses of regional hydrogen sources and sinks for establishing a (regional) hydrogen economy, and systemic, technical technology analyses. In addition, life cycle costing (LCC) and life cycle assessment (LCA) of different technology paths are carried out.

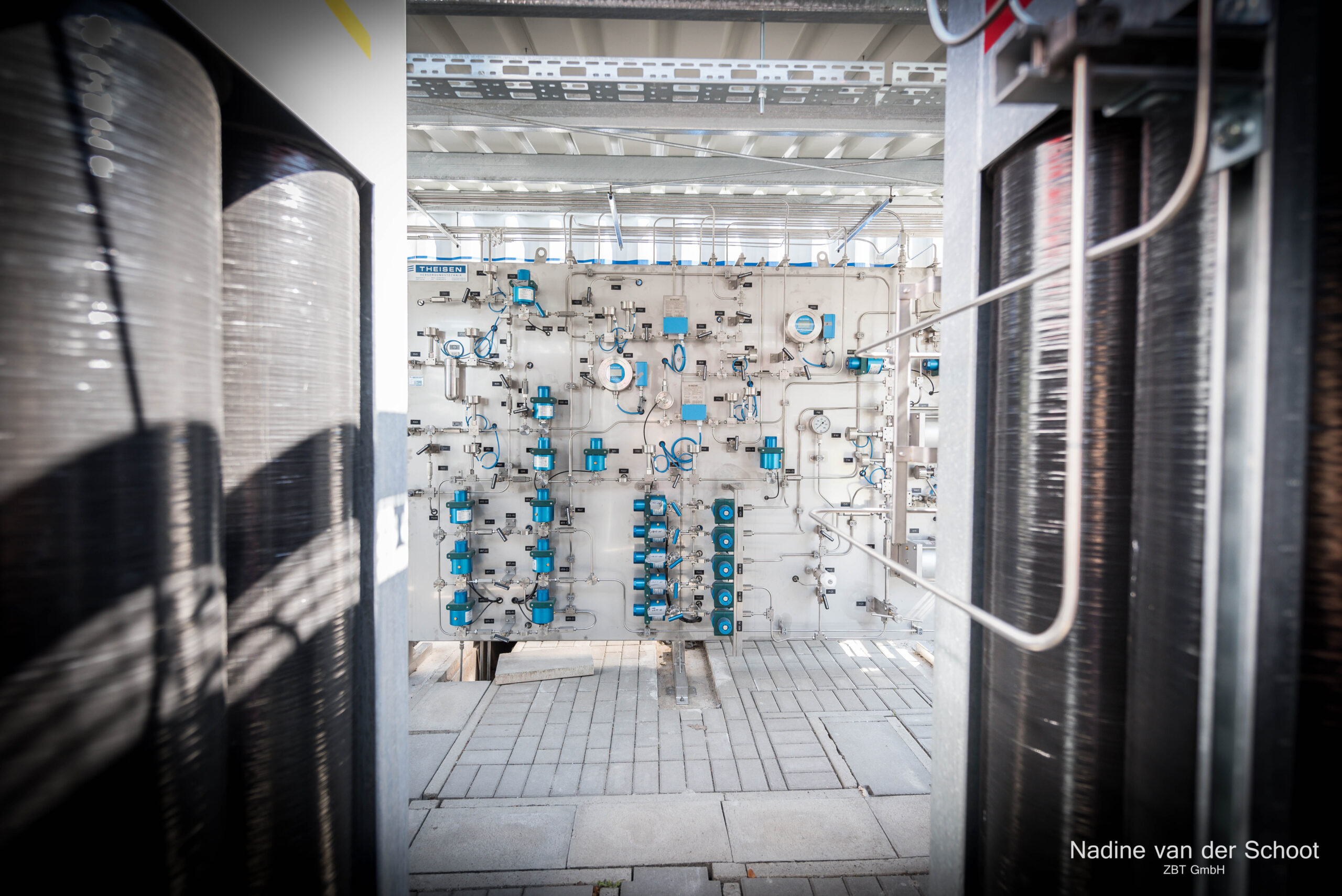

ZBT advises customers and project partners on issues relating to design, safety, approval, certification and permits for the construction and operation of hydrogen facilities (including test benches, production and filling stations). Furthermore, innovative methods for H2 leak detection are being developed and qualified, and automated processes are being developed. In addition, workshops on standardisation, approval and certification are held on a regular basis.