Fuel Cell Systems

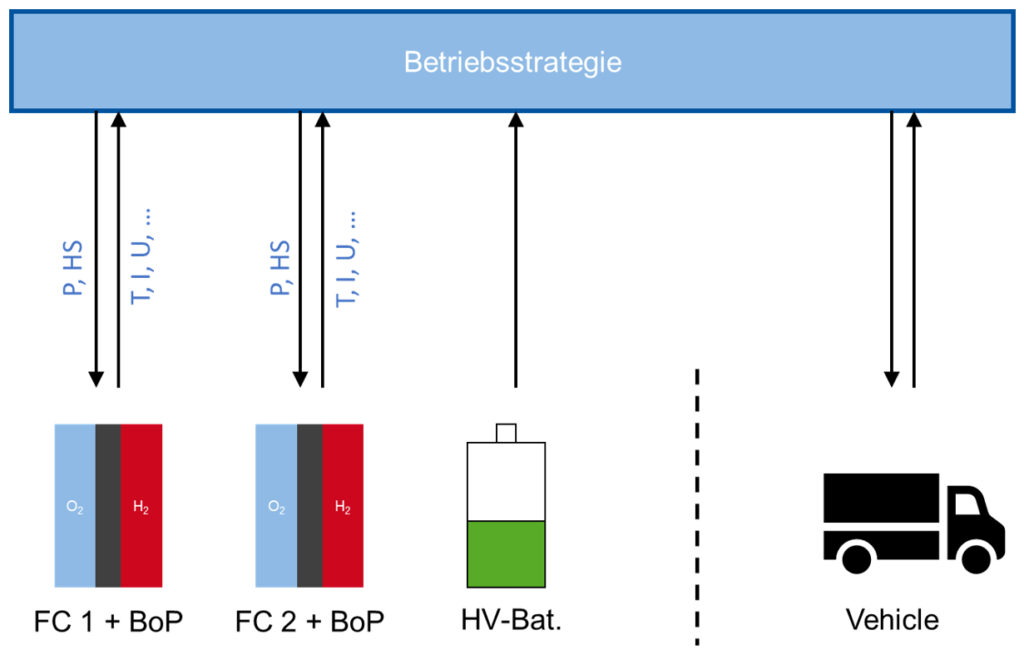

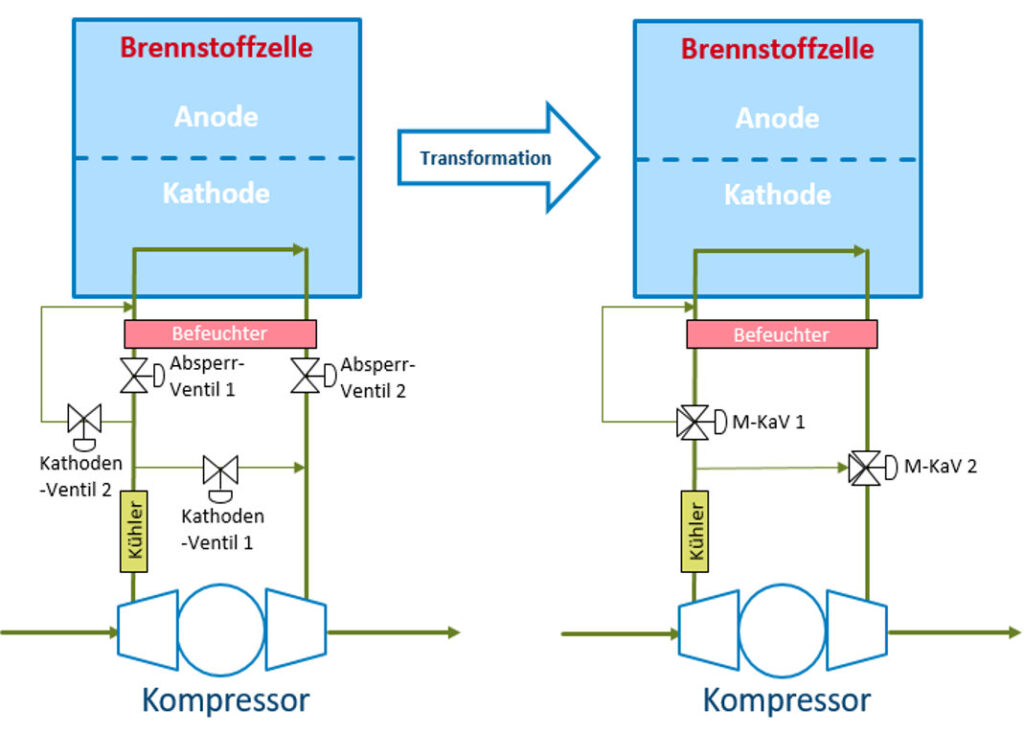

As part of research projects and industrial collaborations, we develop simulation-based fuel cell systems together with our partners.

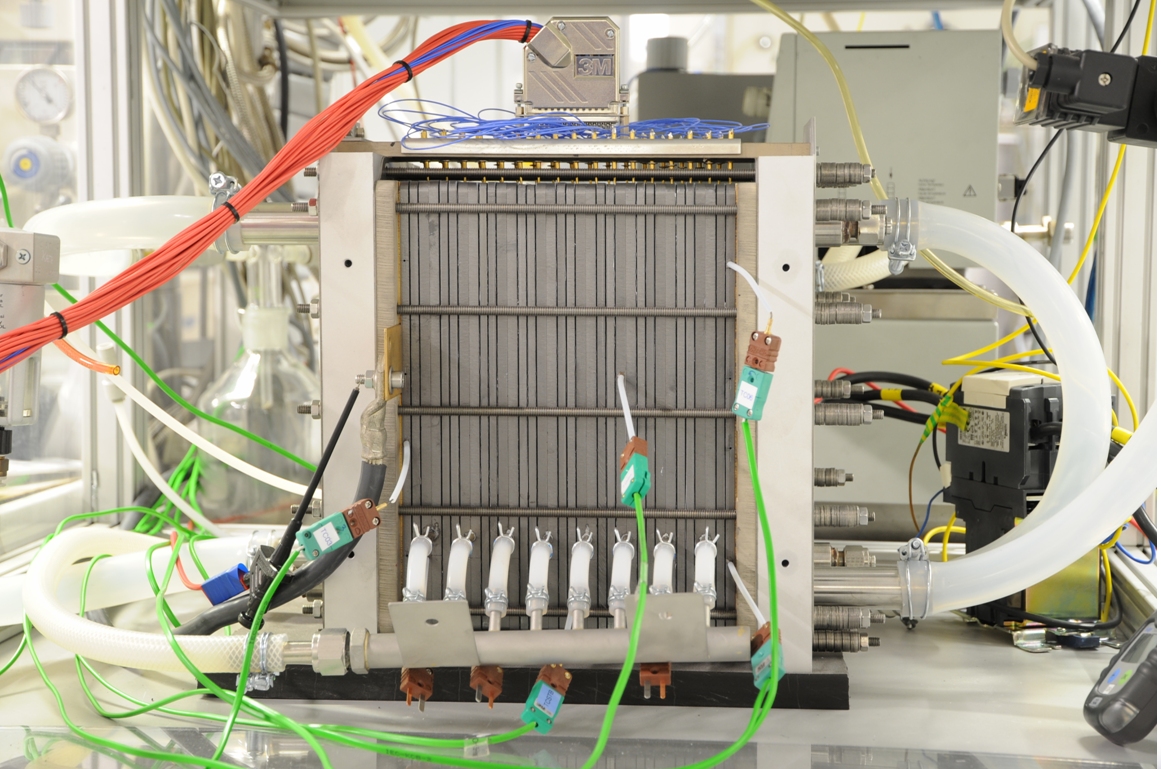

We combine our expertise in system modelling with the operational management of component test benches to simulate real system environments for test tasks.

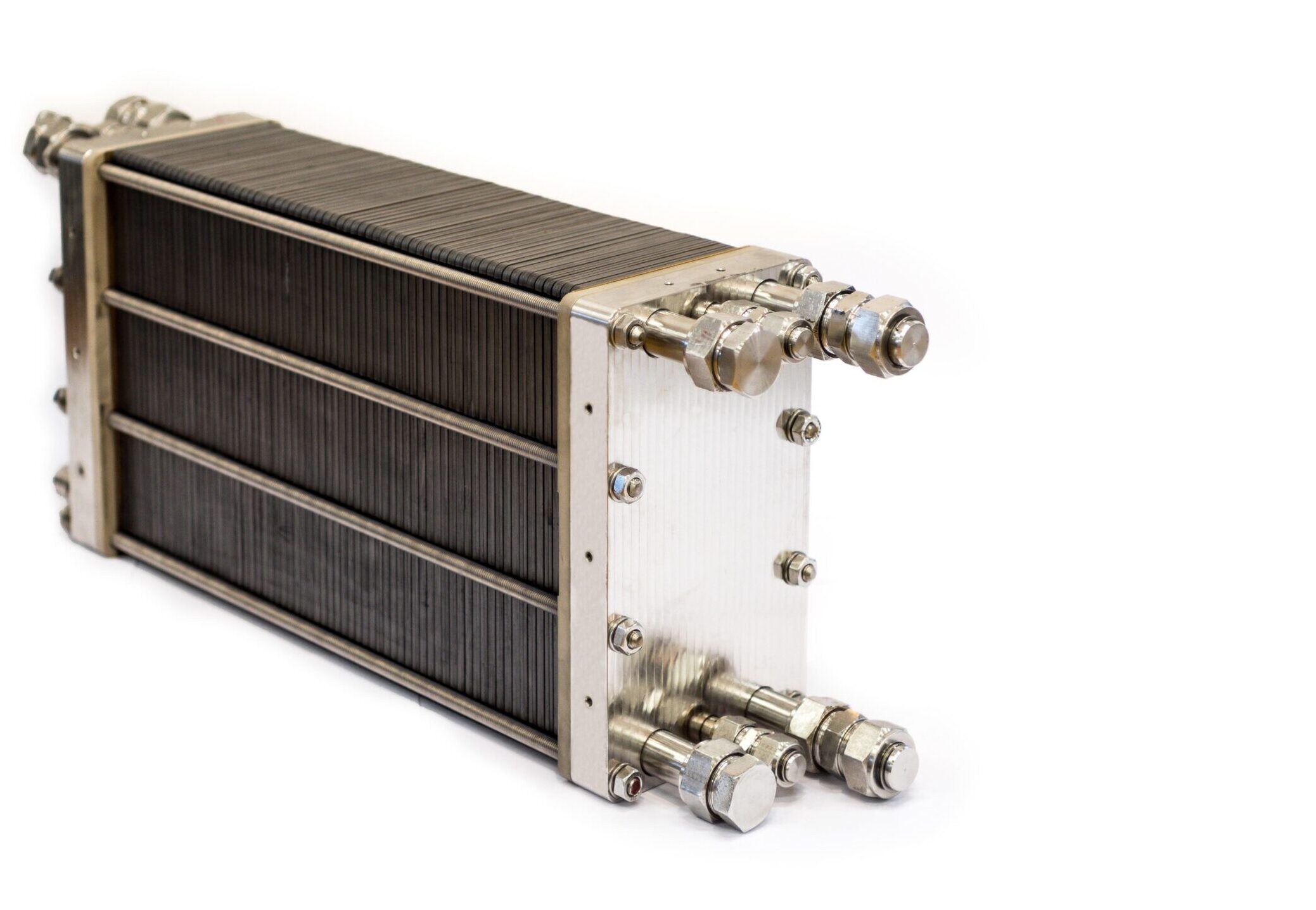

Another focus is on the qualification of system components and materials. The topics of service life optimisation and cost reduction for fuel cell systems and components are addressed through the development of qualification methods with the support of flexible test bench setups.