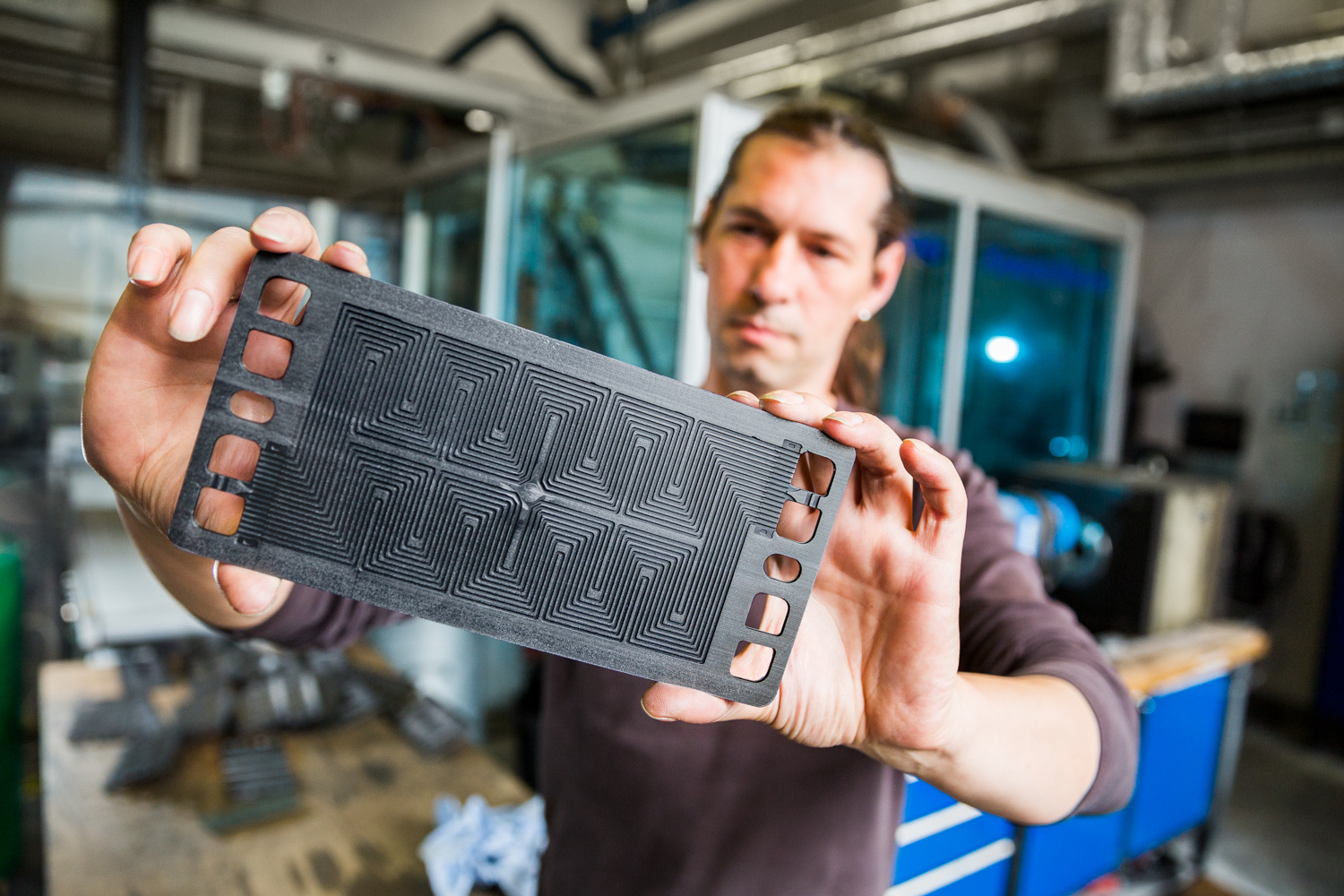

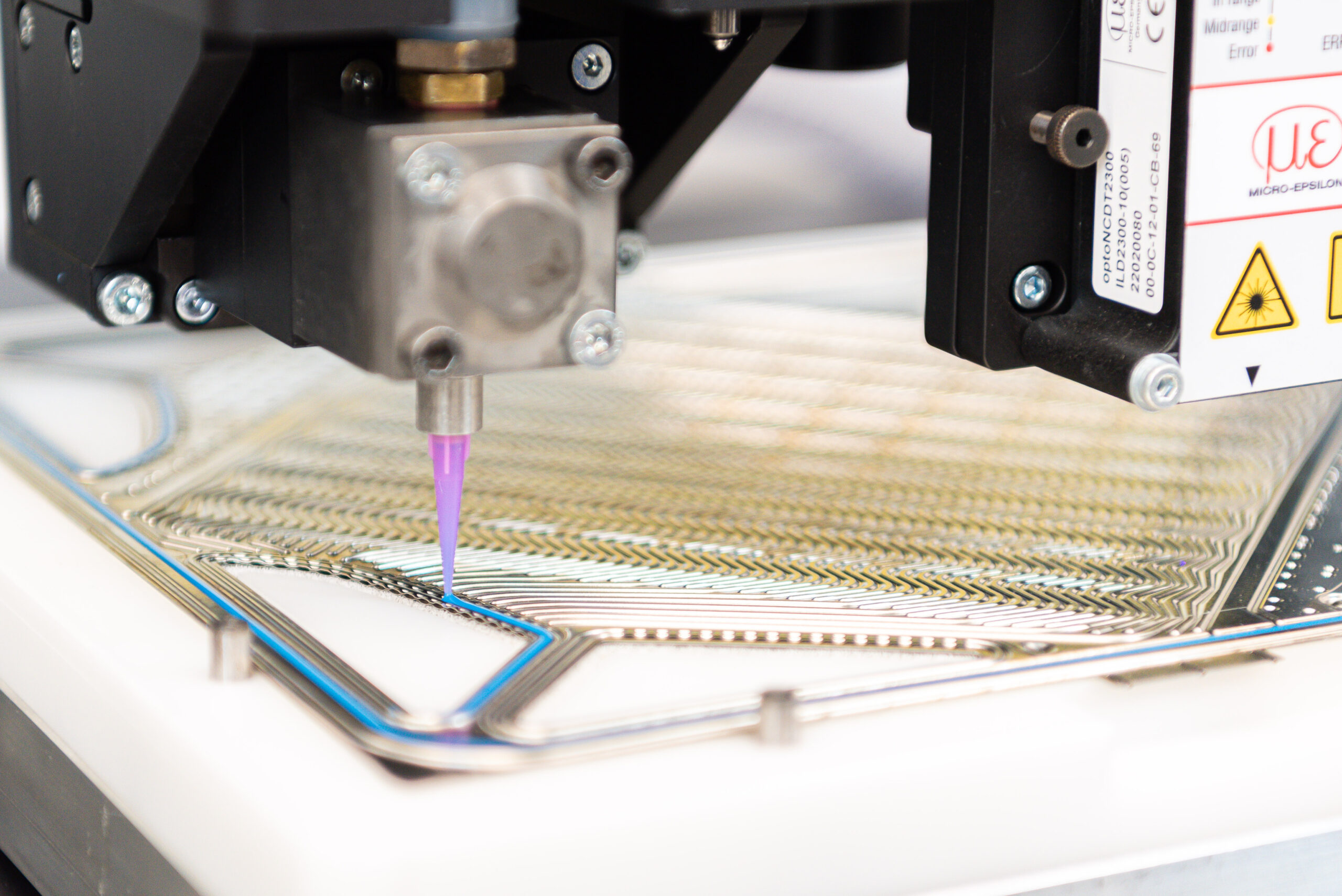

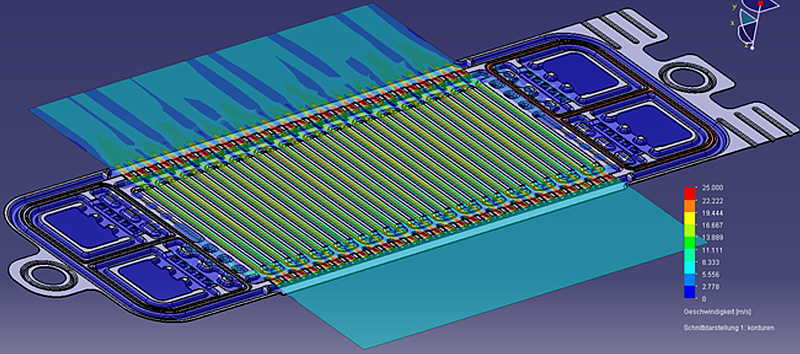

ZBT develops highly filled compounds with carbon-based fillers such as graphite, carbon black, CNT and graphene. These materials are characterised by outstanding electrical and thermal conductivity and excellent chemical resistance. The quality of the starting materials – from raw materials to semi-finished products – is an essential basis for the development of high-performance products.

Our Services

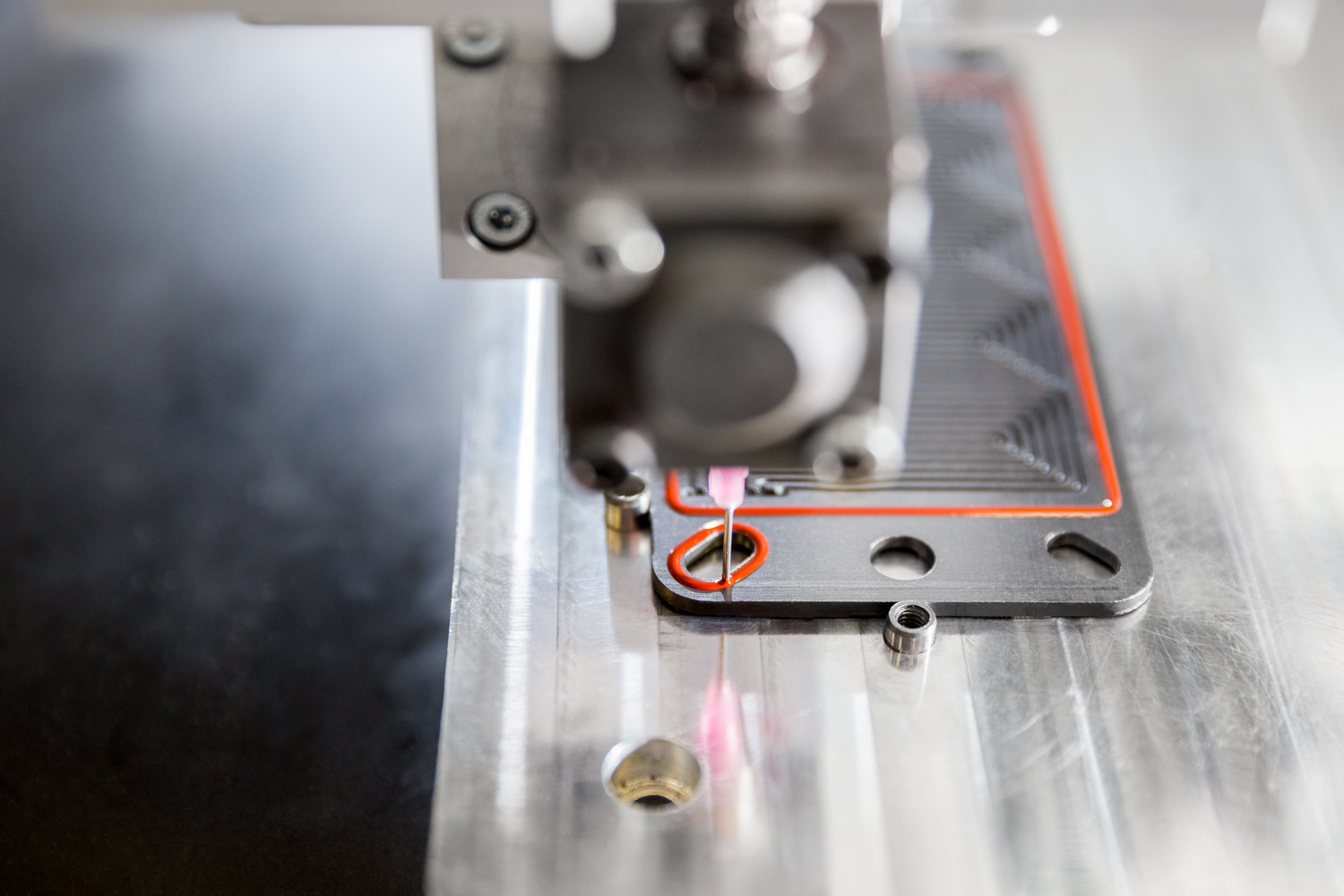

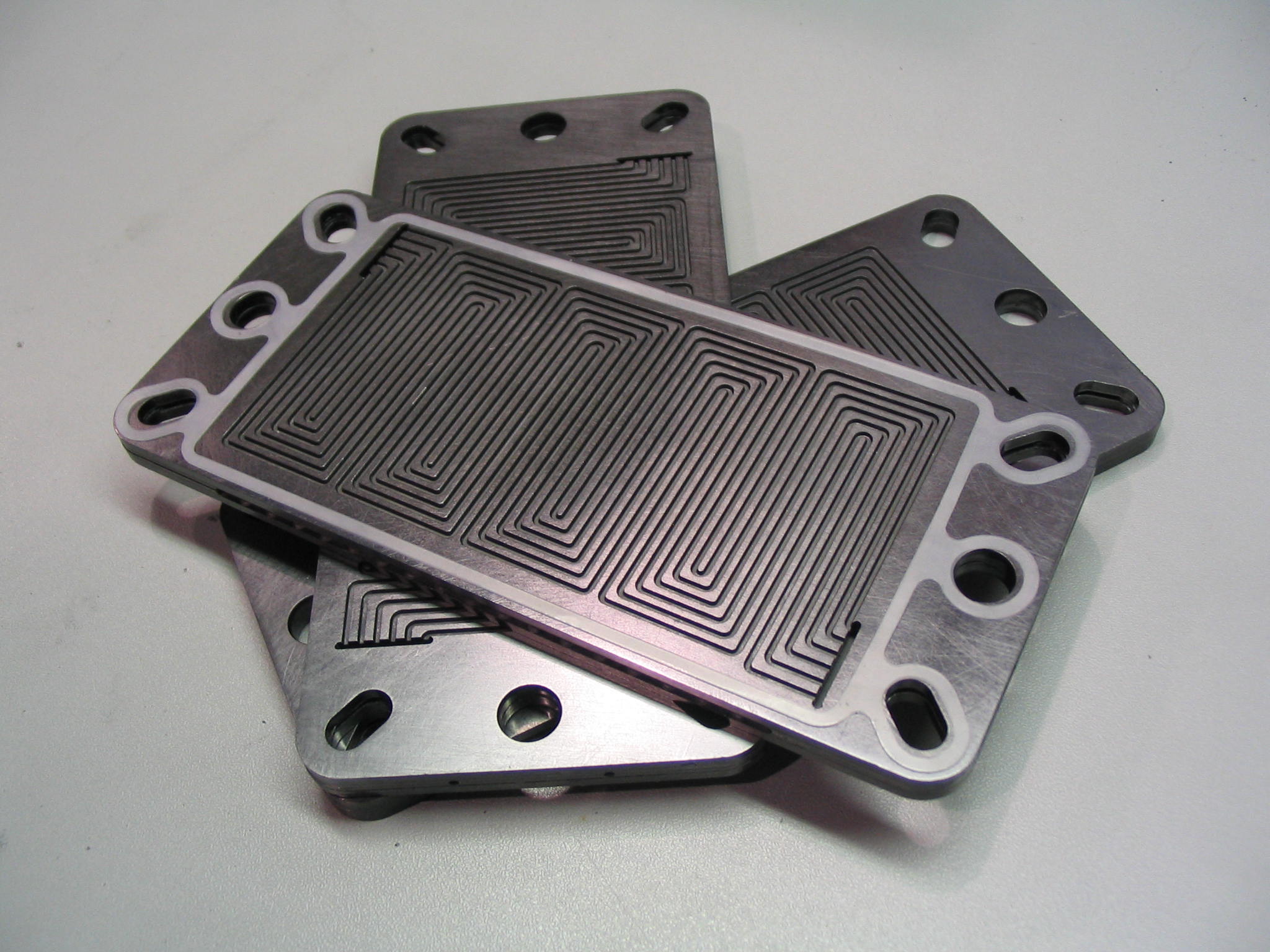

We offer optimised standard materials for various production processes of graphitic bipolar plates suitable for NT-PEM and HT-PEM applications. These materials are distributed worldwide in cooperation with our licensing partners.

In addition, we develop customised compound formulations for individual applications:

- Corrosion-resistant plate and tube heat exchangers

- Electrode materials for fuel cells, batteries and electrolysis

- Heat sinks for efficient heat dissipation