AEM Water Electrolysis

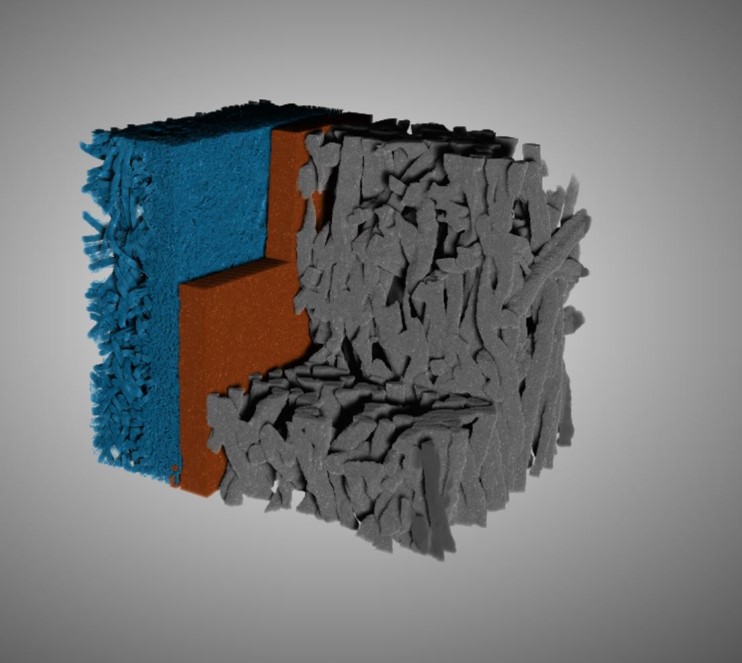

Anion exchange membrane water electrolysis (AEM-WE) combines the advantages of alkaline electrolysis with those of polymer membrane technology. It enables cost-efficient hydrogen production through the use of precious metal-free catalysts. At the same time, proven manufacturing and design principles from PEM technologies can be utilised.

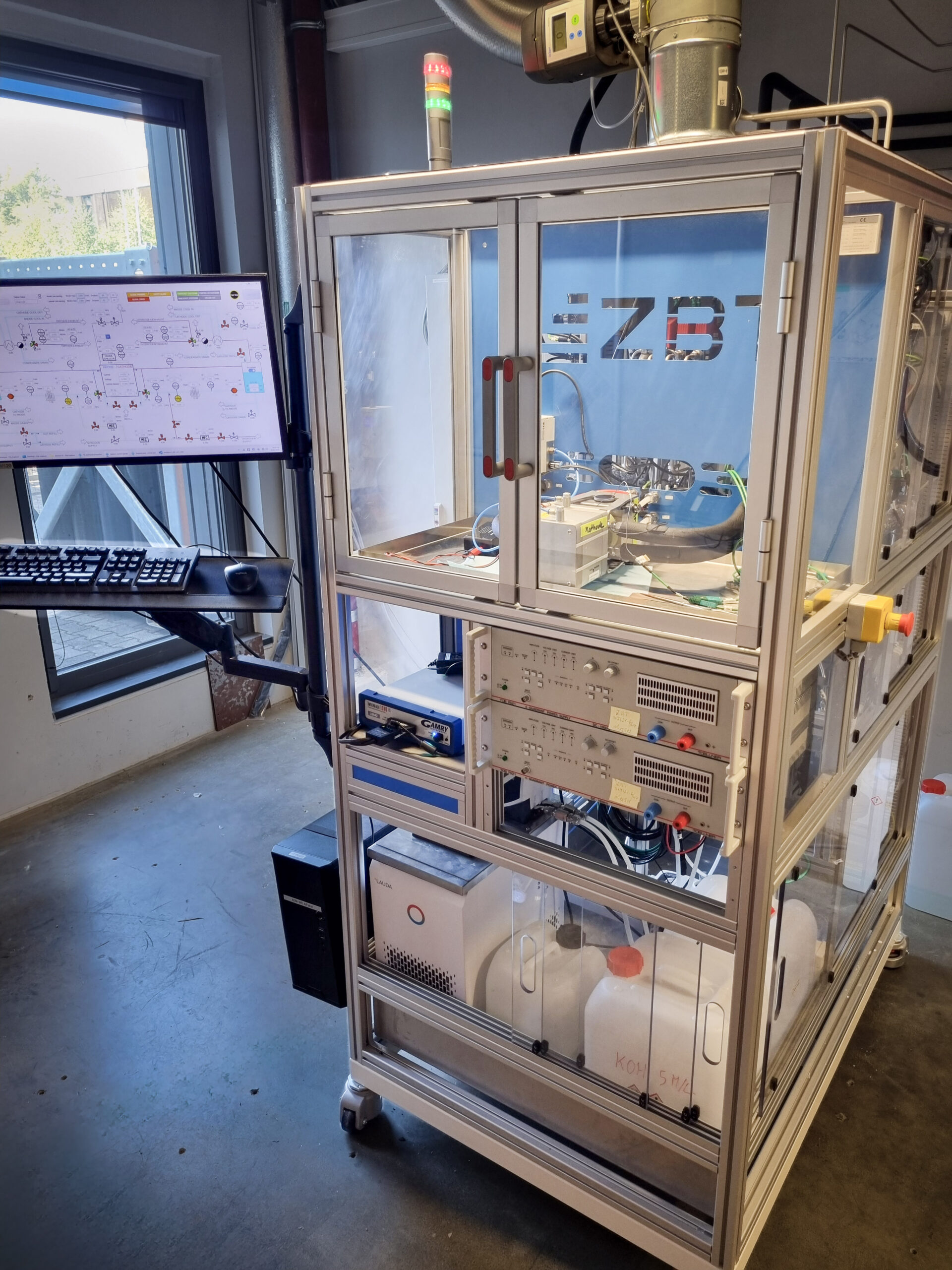

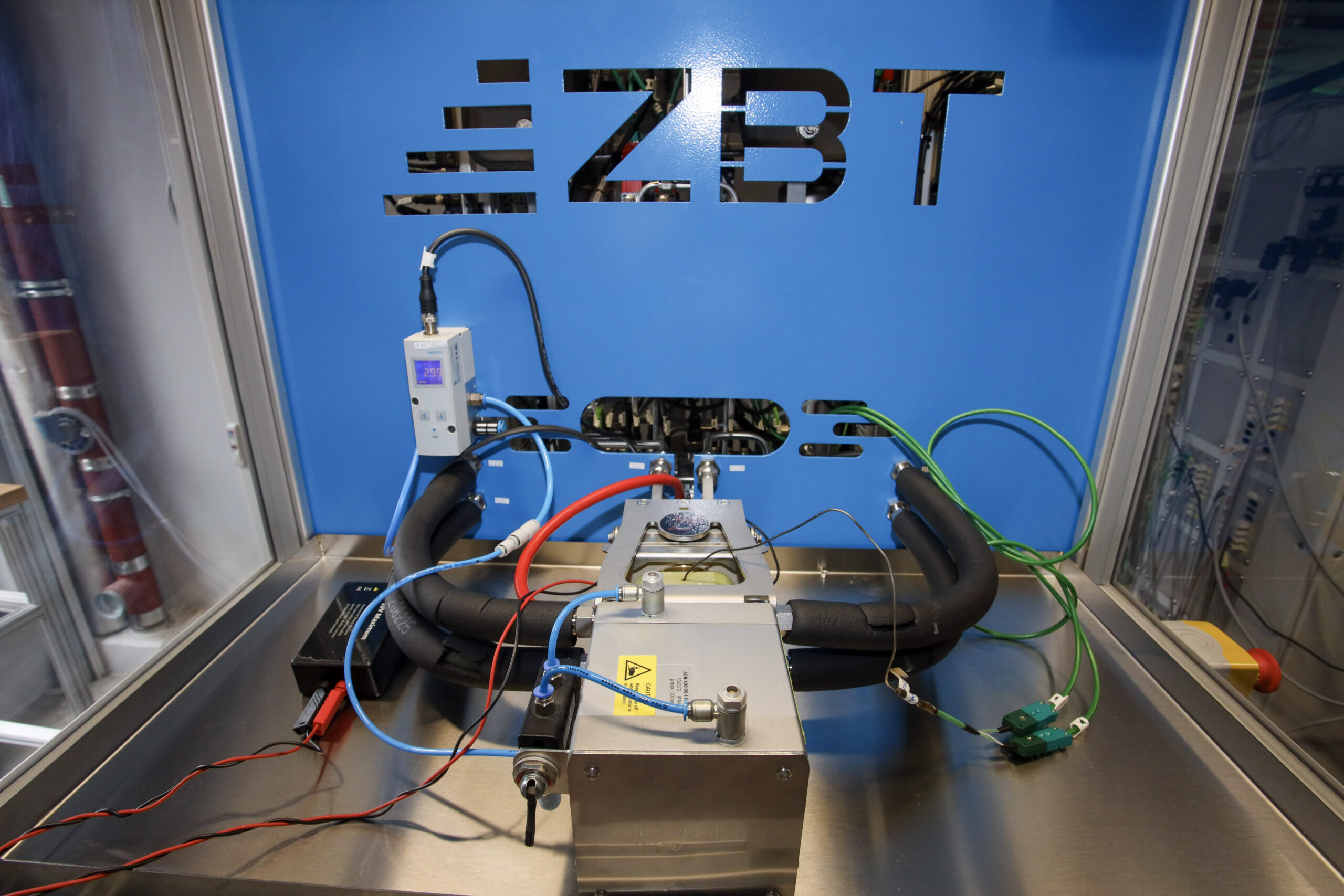

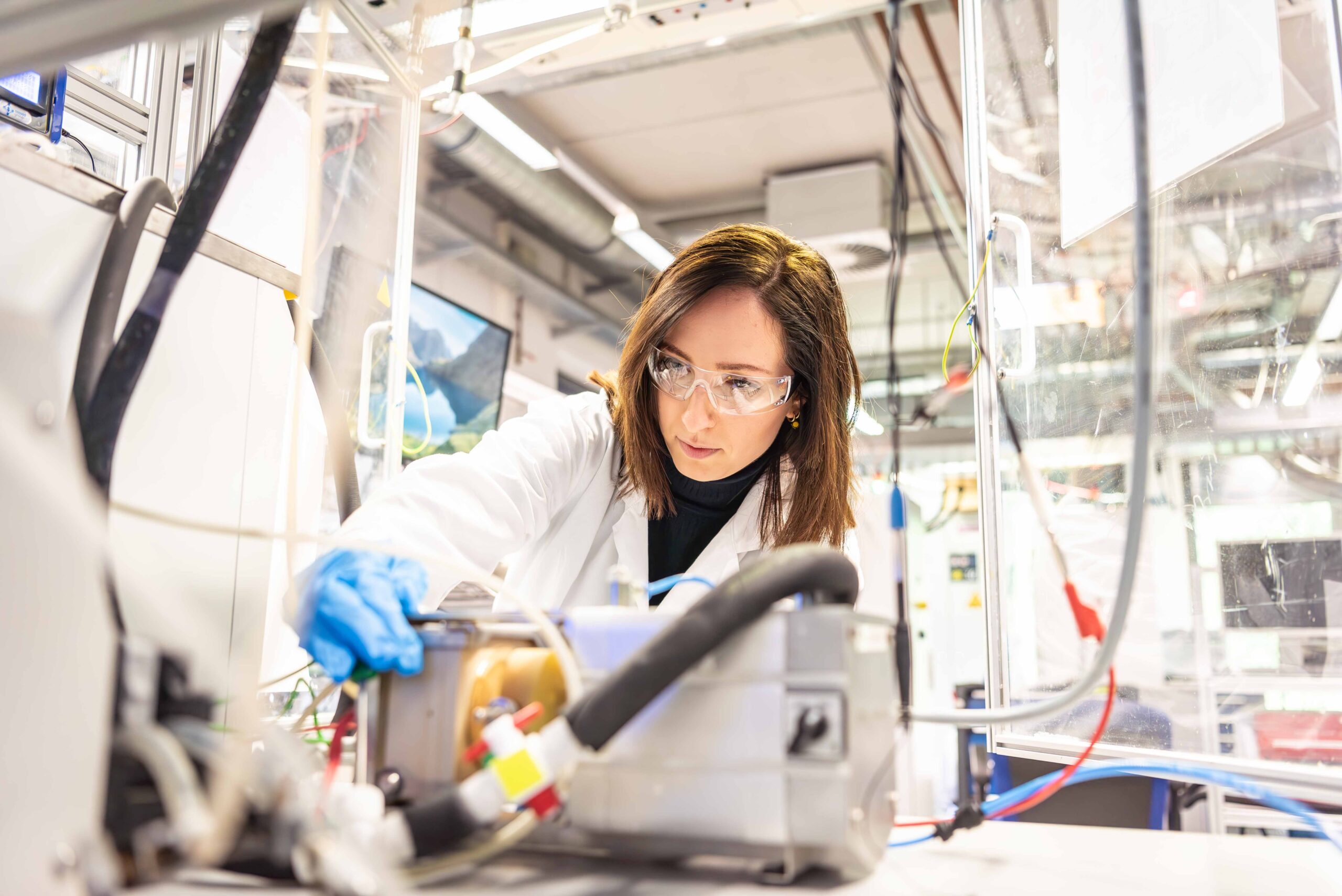

We cover the entire value chain – from the development and synthesis of precious metal-free catalysts to the manufacture and processing of membrane electrode assemblies (MEAs) to system integration and long-term testing. In addition to material development, we optimise production processes and support scaling from the laboratory phase to large-scale implementation.