Optimisation

Electricity generation from green hydrogen is already highly efficient with low-temperature polymer electrolyte membrane (PEM) fuel cells. However, there is still considerable potential for further improvement, particularly through optimised liquid water management.

A key challenge is the accumulation of product water, which obstructs oxygen transport, lowers performance, and shortens the service life of fuel cells. Uneven water distribution within the porous gas diffusion layers and the connected flow channels is still one major challenge. Because of the structural complexity and the interplay of physical processes, currently available simulation methods are not accurate enough to enable optimization under industry-relevant conditions.

Enabling new flow field designs

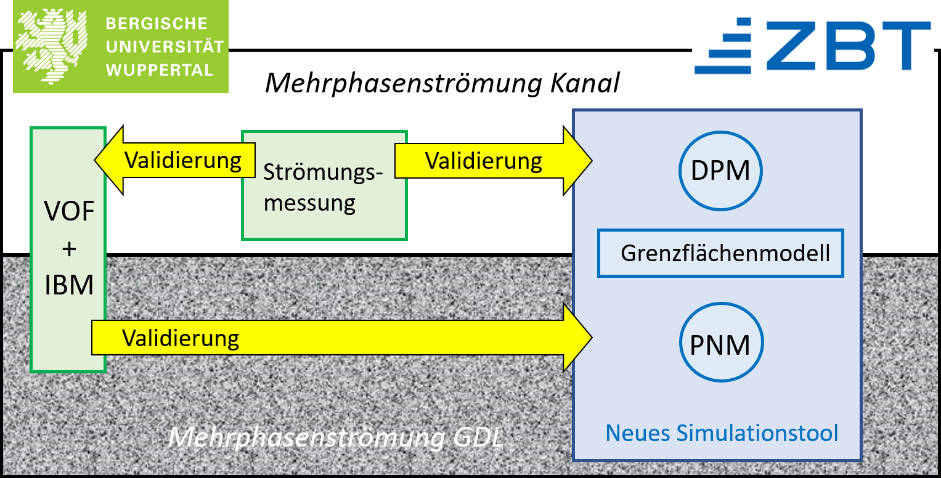

The FLOWMEX project aims to fundamentally improve water management in fuel cells. The focus is on developing and validating a new, computationally efficient simulation tool that realistically maps the transport of liquid water in gas diffusion layers and flow field channels. With the help of these models, new flowfield designs are developed, constructively evaluated and validated in test fuel cells.

The simulation model is provided as an open source tool. This also gives small and medium-sized enterprises (SMEs) the opportunity to develop components more efficiently and without expensive high-performance computers or commercial software.

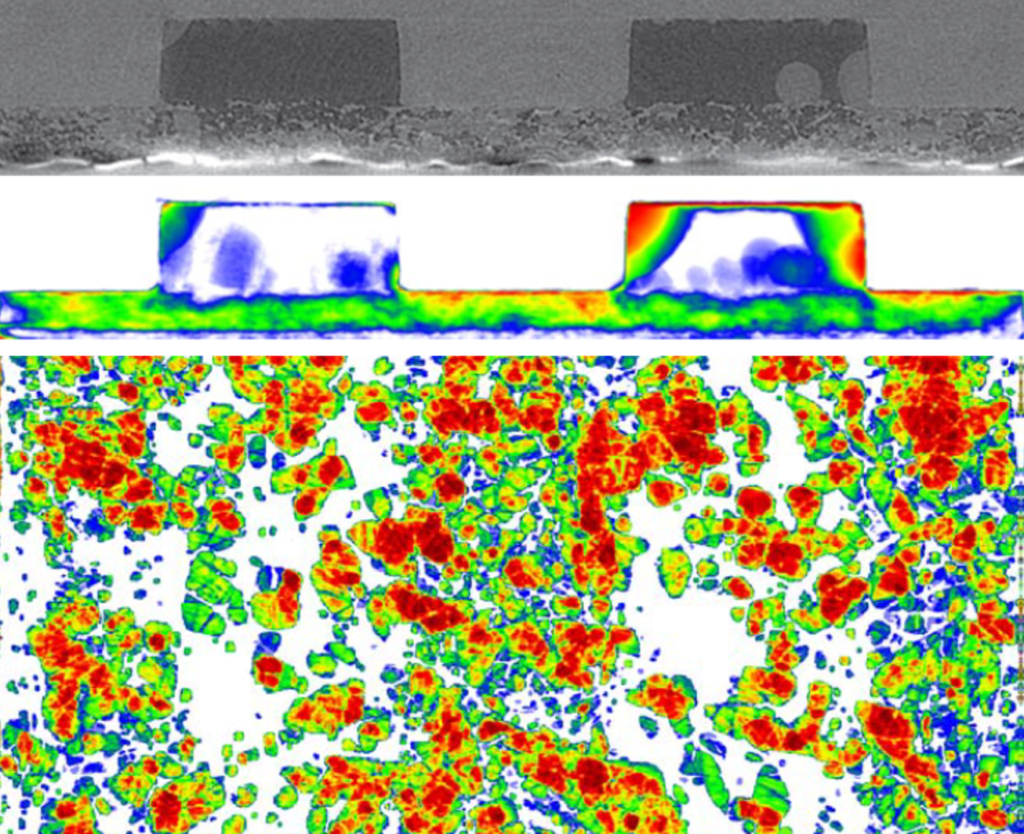

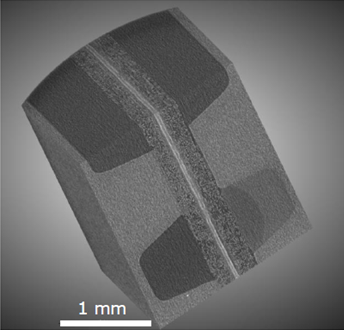

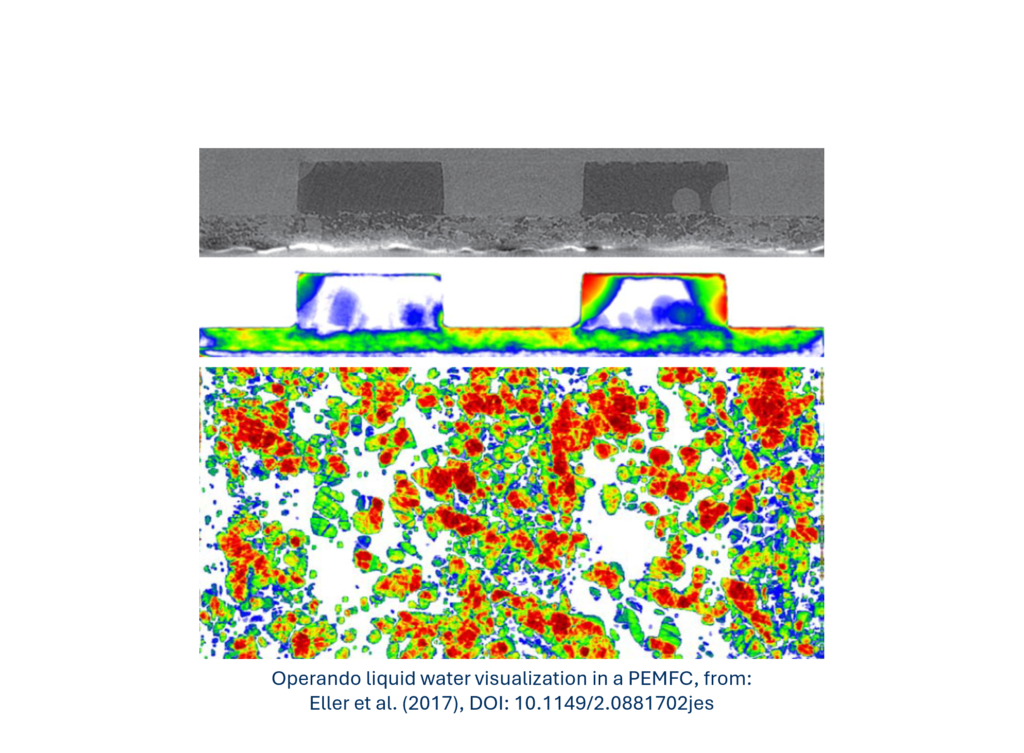

Liquid water visualisation using XTM in the GDL and channels of an operating fuel cell, from:

J. Eller, J. Roth, F. Marone, M. Stampanoni, und F. N. Büchi, „Operando Properties of Gas Diffusion Layers: Saturation and Liquid Permeability“, J. Electrochem. Soc., Bd. 164, Nr. 2, S. F115–F126, 2017, doi: 10.1149/2.0881702jes.

Liquid water visualisation using XTM in the GDL and channels of an operating fuel cell, from:

J. Eller, J. Roth, F. Marone, M. Stampanoni, und F. N. Büchi, „Operando Properties of Gas Diffusion Layers: Saturation and Liquid Permeability“, J. Electrochem. Soc., Bd. 164, Nr. 2, S. F115–F126, 2017, doi: 10.1149/2.0881702jes.

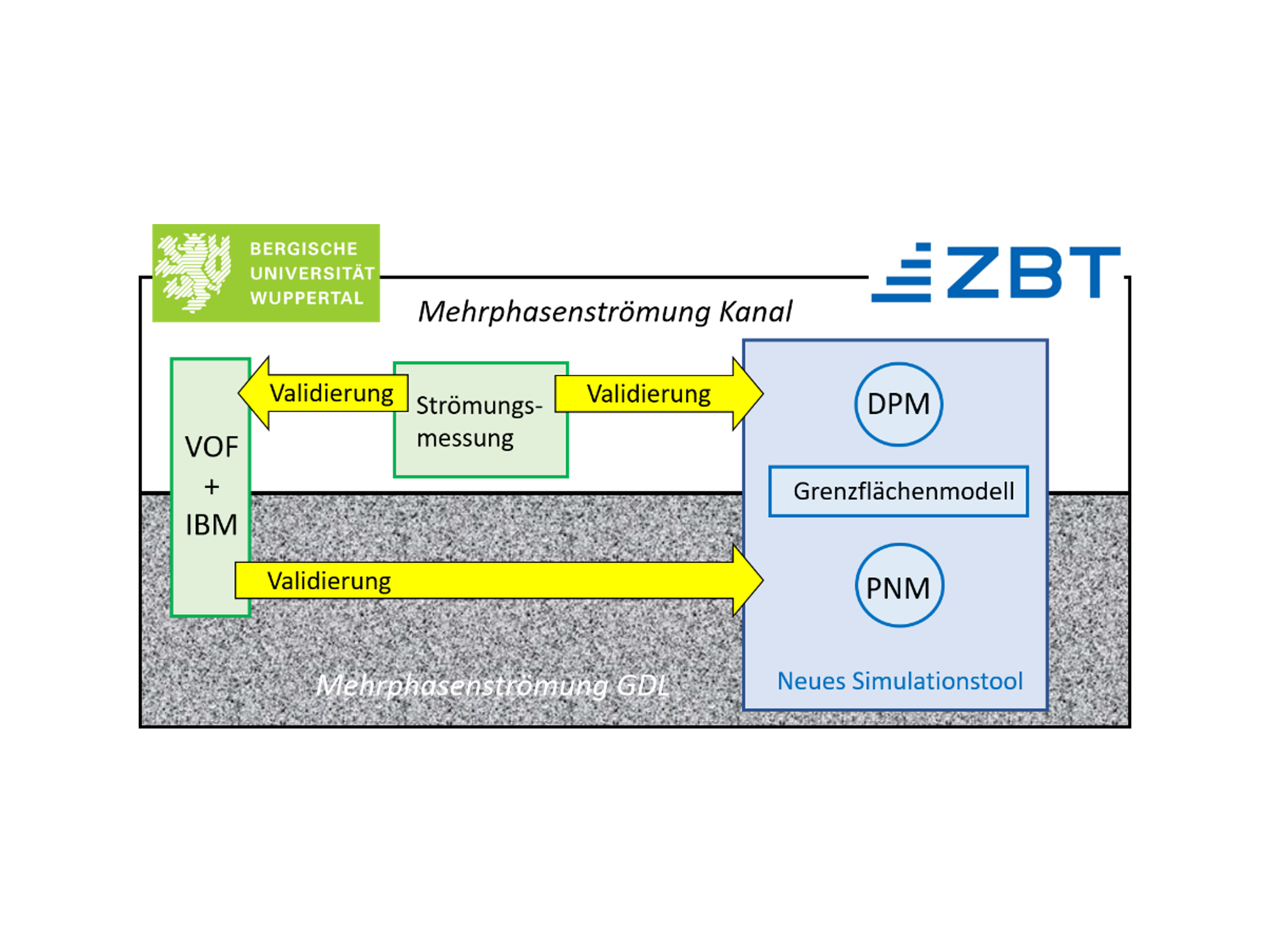

Solution approach for developing the planned simulation method: coupling of DPM and PNM via an interface model (blue elements = ZBT focus areas) and necessary validations/verifications (yellow arrows) via detailed VOF+IBM simulations and experiments (green elements = LSM focus areas) | IBM = Immersed Boundary Method

Solution approach for developing the planned simulation method: coupling of DPM and PNM via an interface model (blue elements = ZBT focus areas) and necessary validations/verifications (yellow arrows) via detailed VOF+IBM simulations and experiments (green elements = LSM focus areas) | IBM = Immersed Boundary Method