The results show that the combination of nickel and sulfur creates a particularly active and corrosion-stable surface for oxygen evolution.

The key properties of this material combination are:

- Active nickel hydroxide and nickel oxide hydroxide phases, which contribute significantly to OER in alkaline media

- Modification of the electronic structure of nickel by sulfur, which improves the adsorption of oxygen intermediates

This results in low overpotentials for OER and higher current densities.

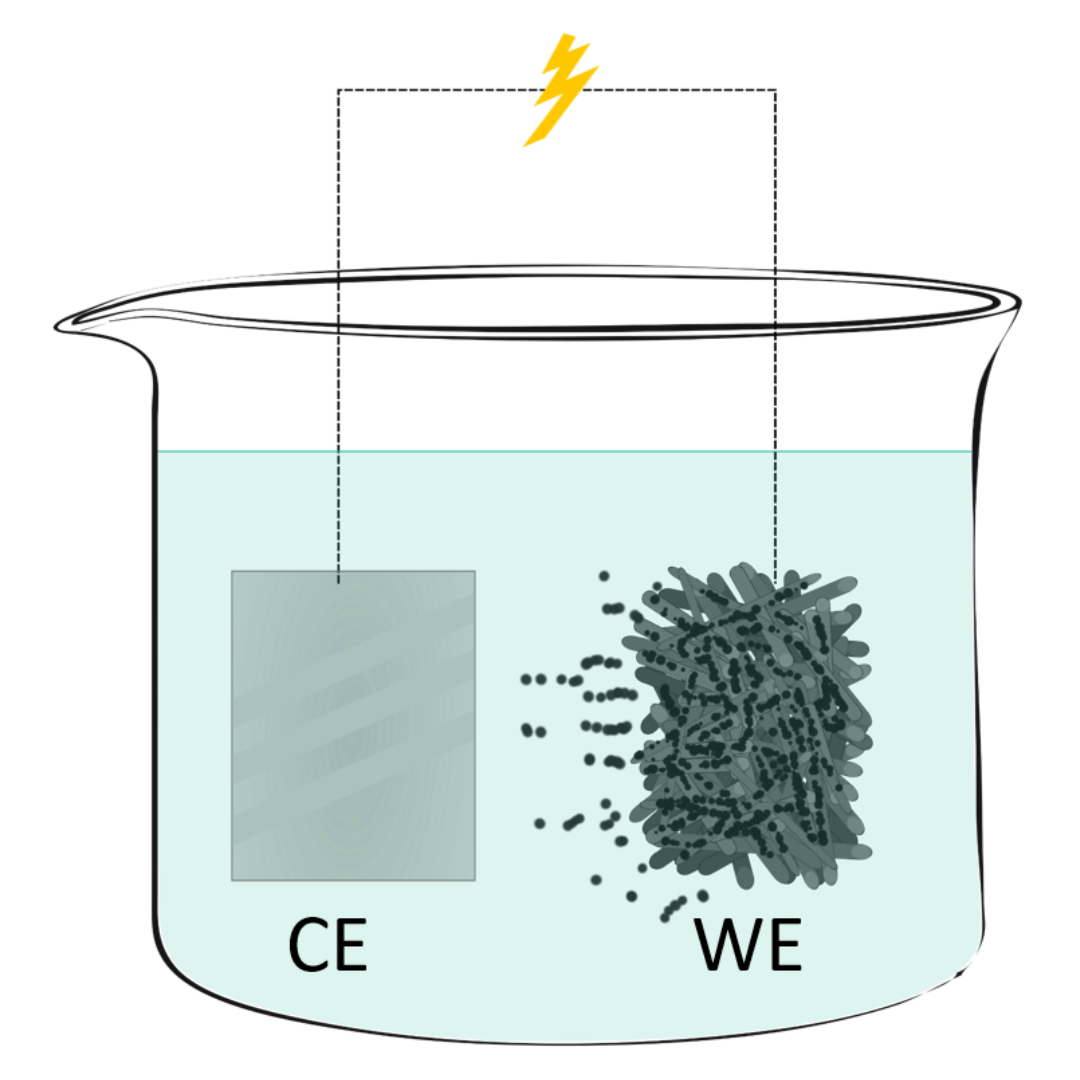

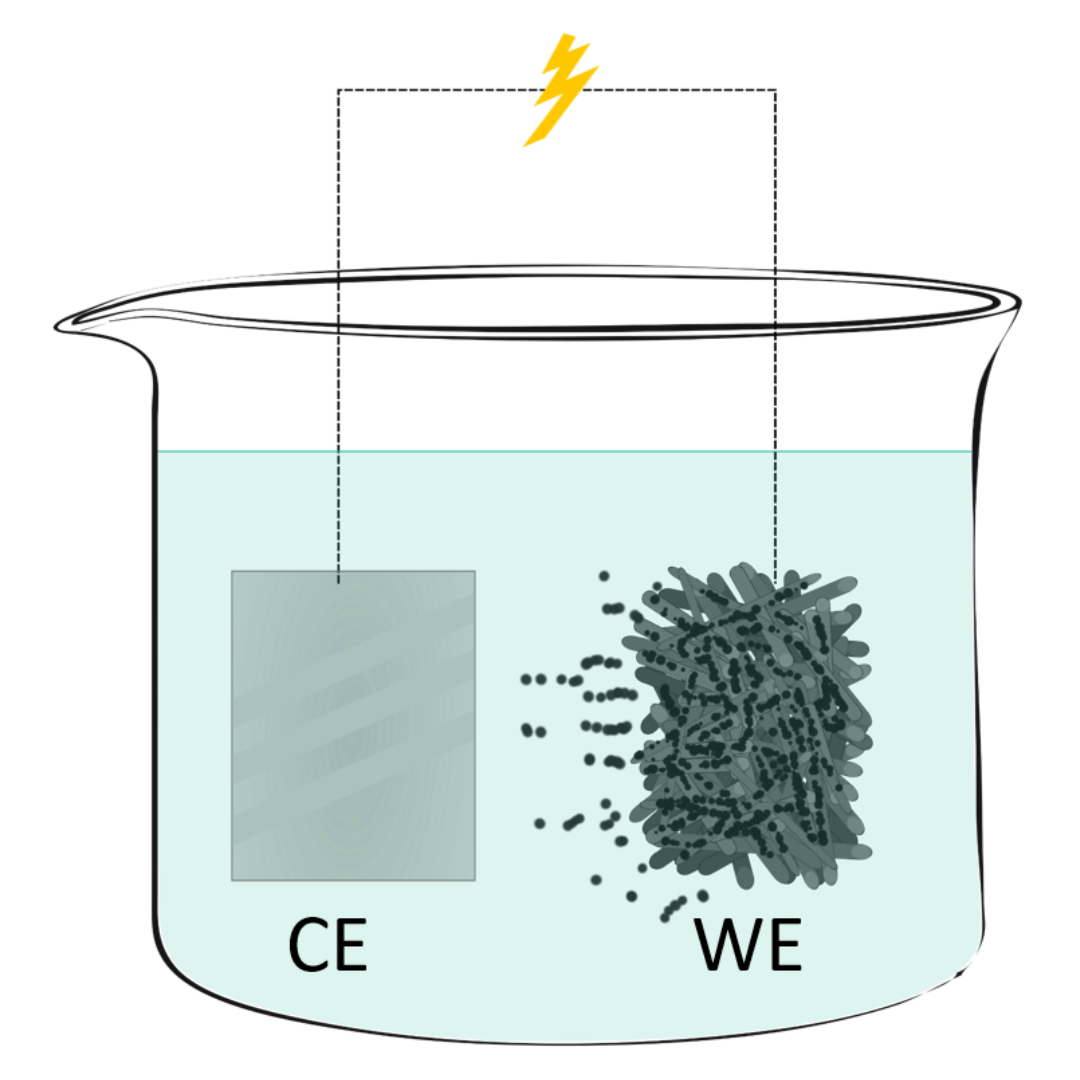

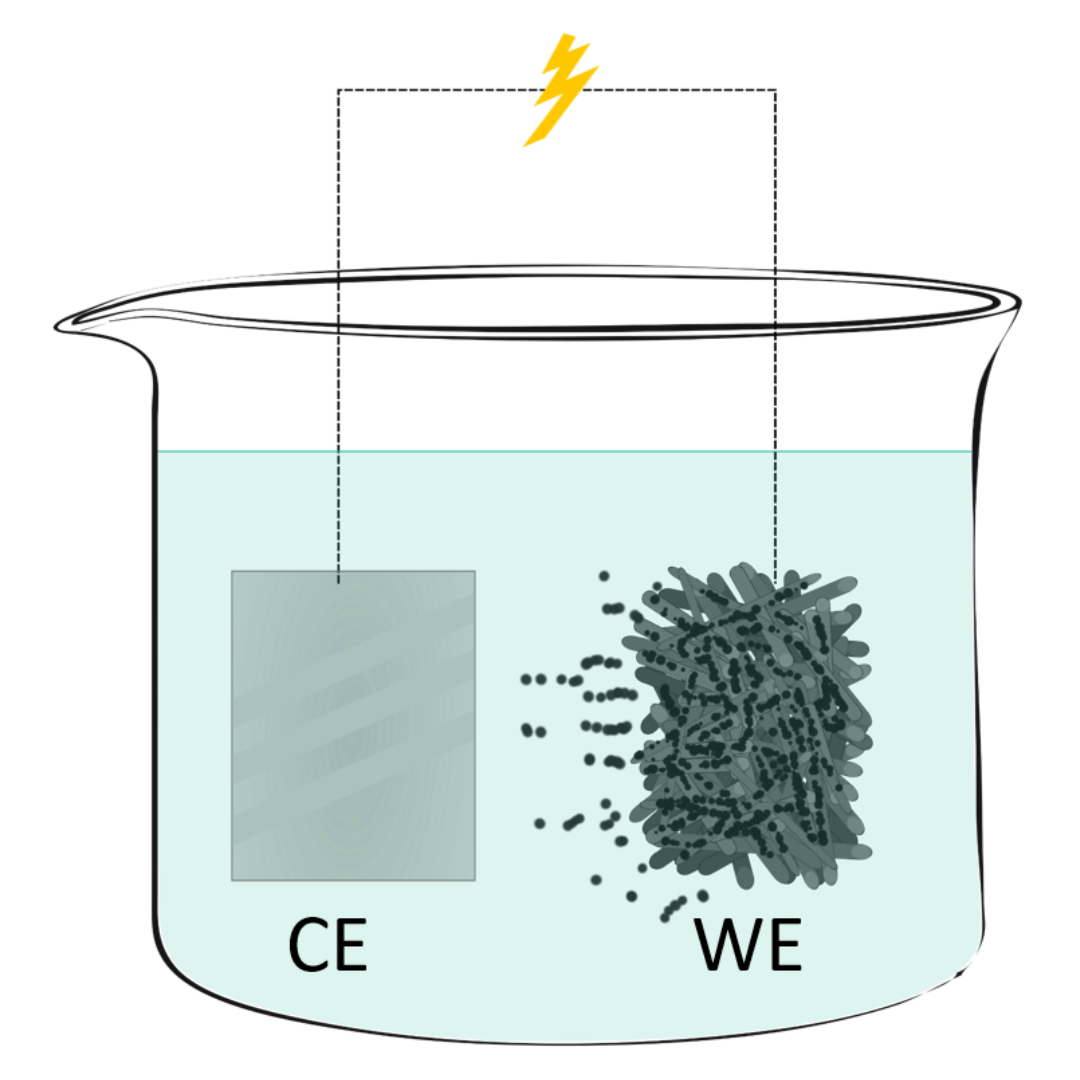

The key innovation lies in electrochemical deposition. This process allows precise control of the composition and structure of the catalyst layer. At the same time, the process is scalable and therefore suitable for industrial applications.

“While laboratory research has produced many promising materials in recent years, the current challenge is to translate these concepts into practical electrolysis applications and test their performance and stability under realistic operating conditions,” explains Miriam Hesse, doctoral student at ZBT and co-author of the publication. “With this study, we have now taken a big step forward.”

Special thanks go to co-authors Mila Manolova (fem), Jonas Lieb (fem), Ivan Radev (ZBT), Dr Şeniz Sörgel (fem), Prof. Dr Holger Kaßner (fem), Thomas Ernst Müller (Ruhr University Bochum) and Prof. Dr Ulf-Peter Apfel (Ruhr University Bochum).