Equipment

We have high-end laboratories with wet chemistry, a wide range of measuring instruments and commercial and custom-developed test benches. Our hydrogen quality laboratory, Hy-Lab, is one of only two laboratories of its kind in Germany and specialises in determining the purity of hydrogen samples and analysing contaminants. At our hydrogen test field, we can examine the interaction of systems and components of a hydrogen infrastructure on a 1:1 scale. At our hydrogen test station, we also further develop hydrogen refuelling stations (HRS) and their components, including the development of refuelling protocols, especially for heavy-duty applications.

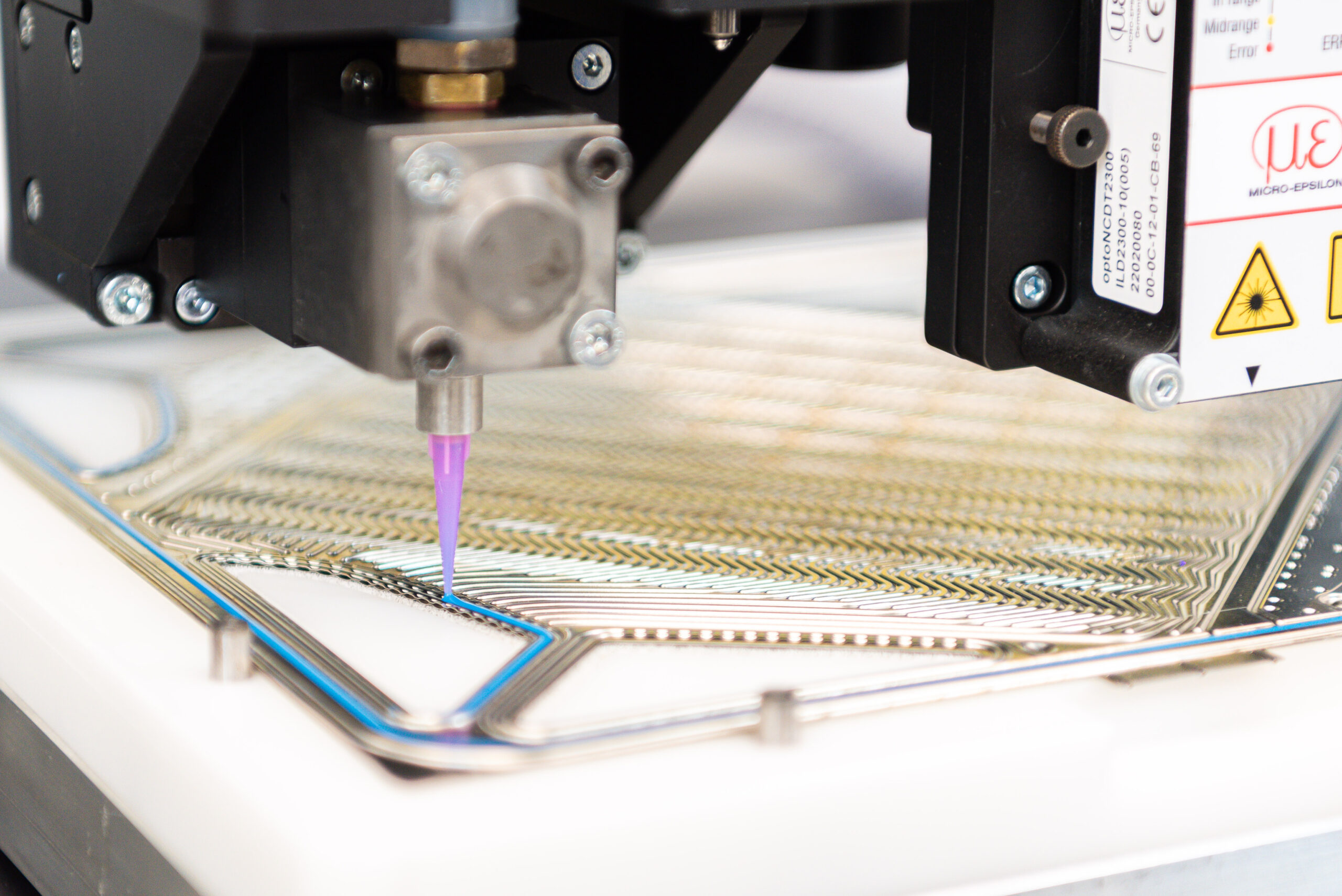

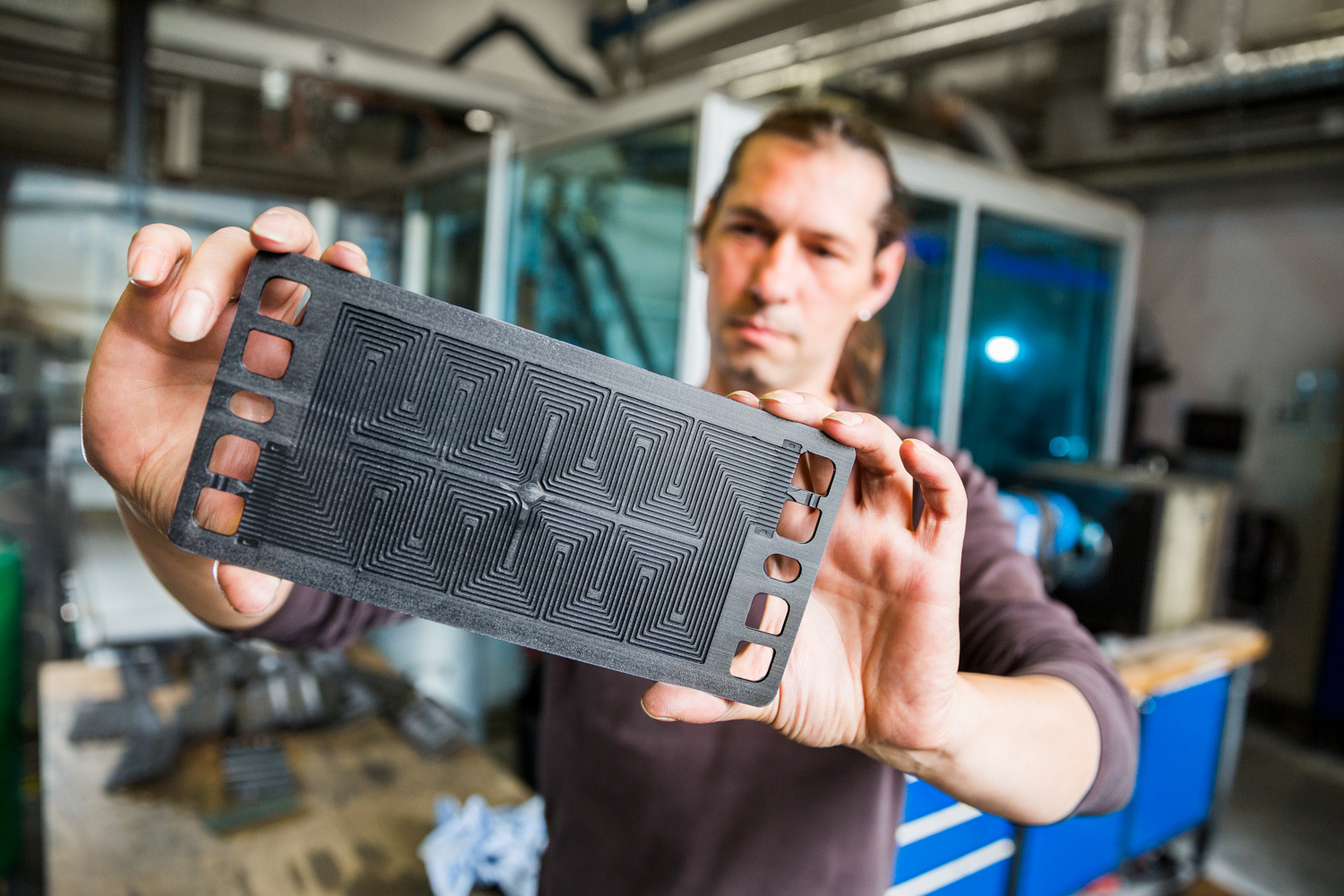

Analytical instruments

Precise analysis is the basis for the development of innovative materials and processes. At ZBT, state-of-the-art equipment for material and process analysis is available. In addition to classic material testing, we offer specialised analysis methods for hydrogen and its properties.