Electrochemical Components Department

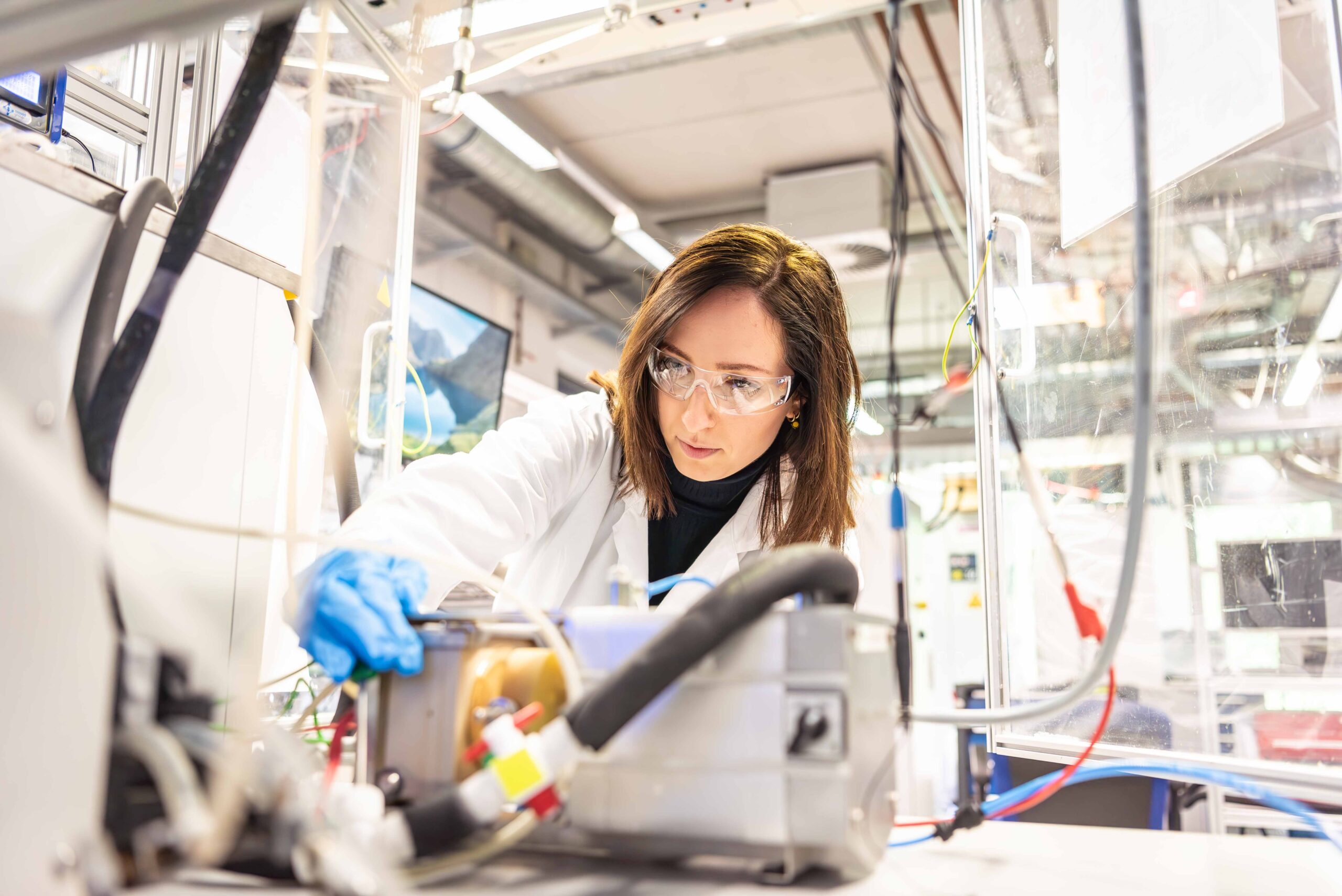

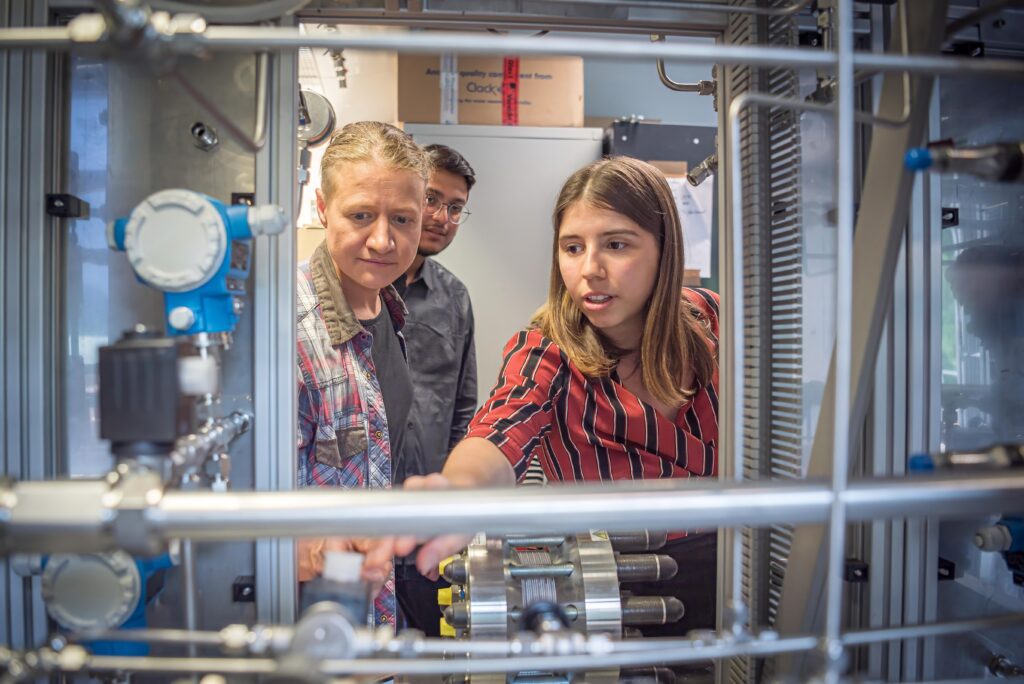

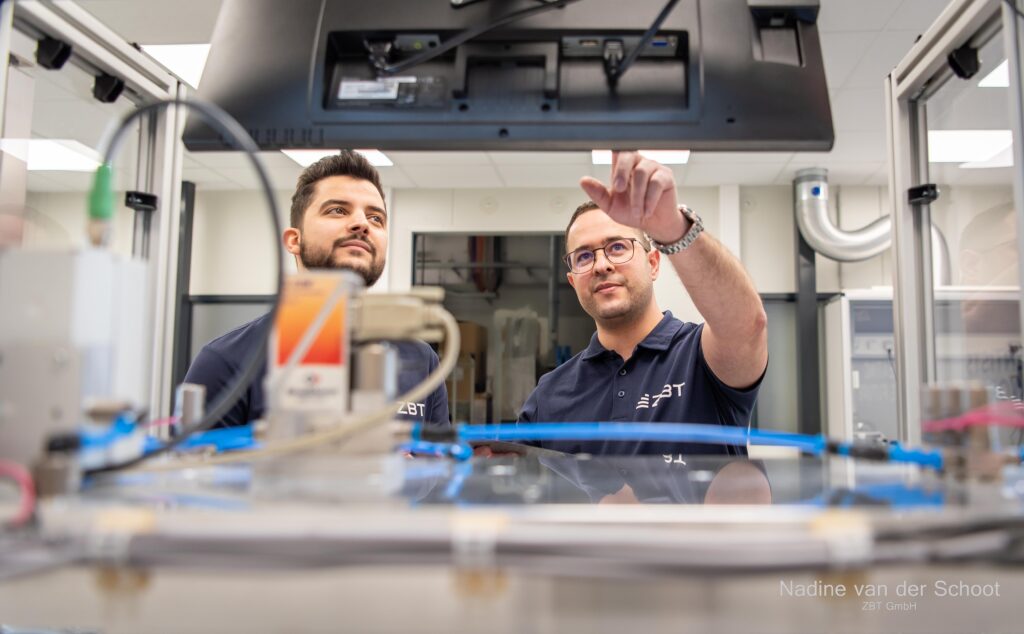

The Electrochemical Components department aims to break down the processes in electrochemical energy conversion systems such as fuel cells and electrolysis cells in detail and optimize them systematically.

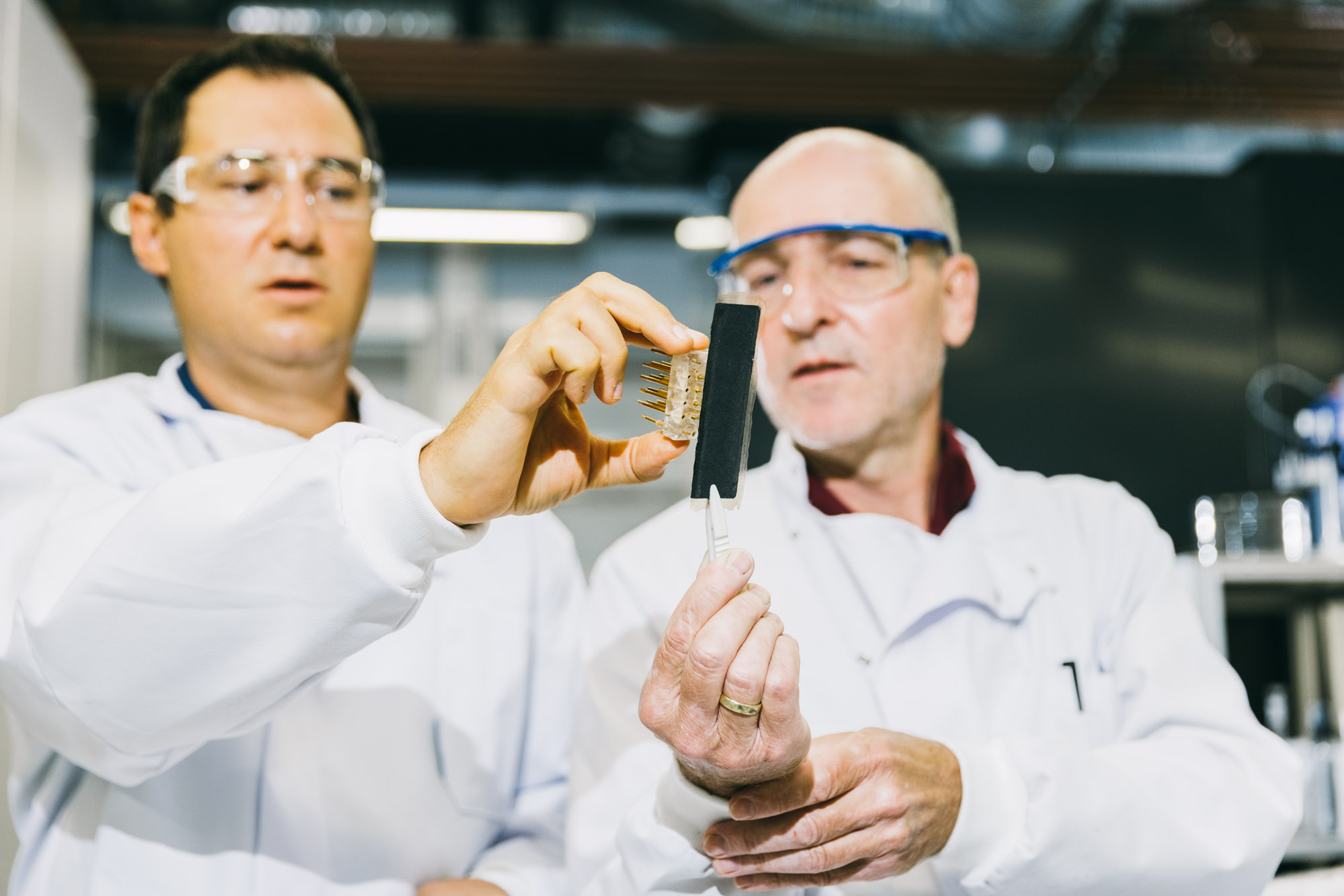

This involves the use of state-of-the-art electrochemical and physical analysis methods, innovative architectures, and scalable manufacturing processes for individual components and membrane electrode assemblies (MEAs).

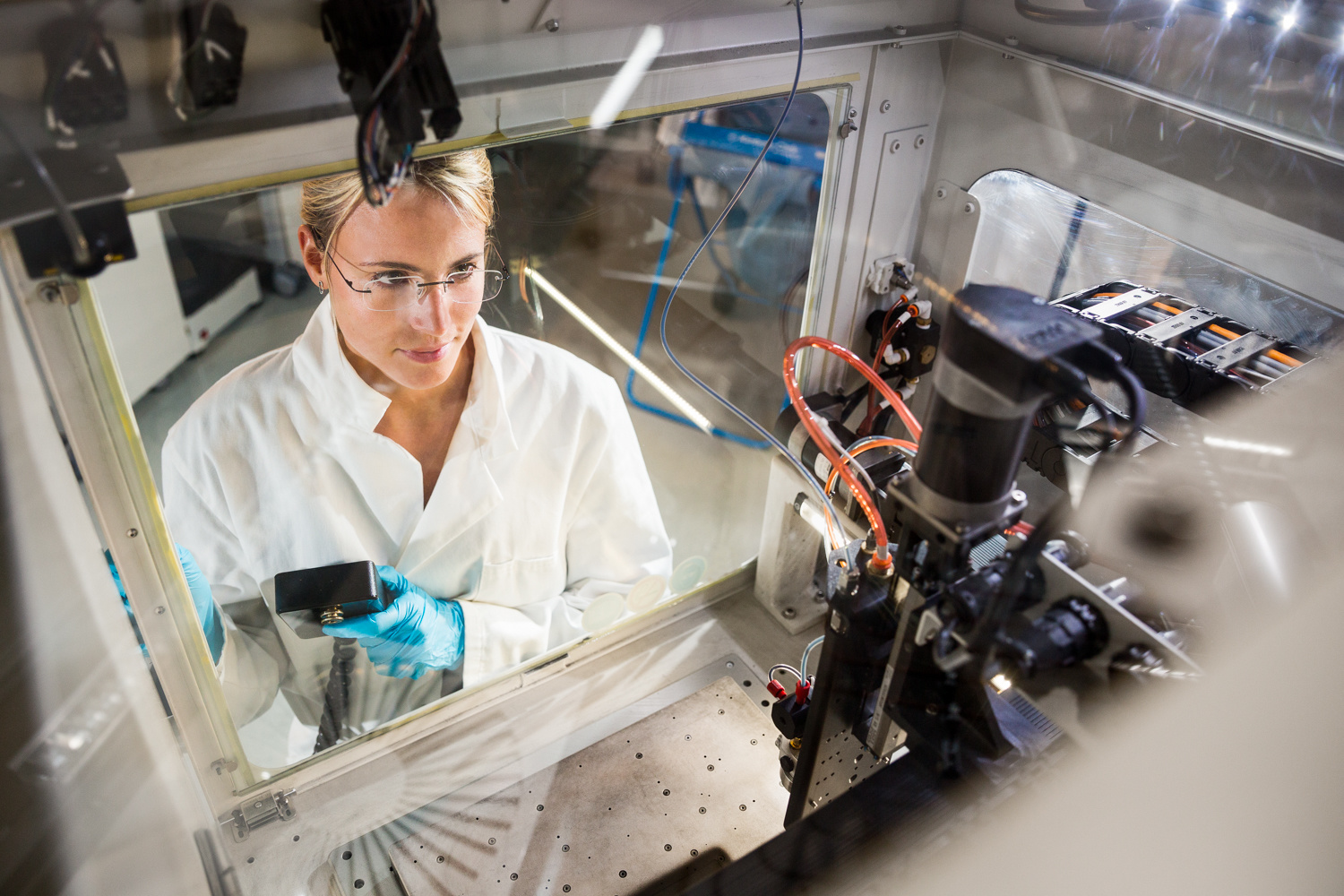

MEA Development and Electrocatalysis

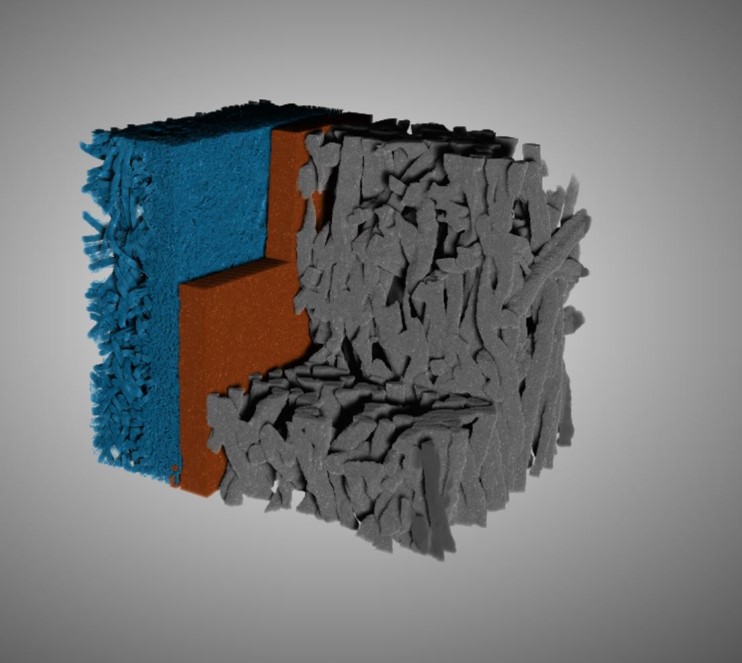

The science-oriented MEEK group specialises in the development and optimisation of highly innovative MEA components from the nano to the layer level. This includes, for example, the use of novel electrocatalysts, including innovative catalyst supports, precious metal-free or reduced active species, and custom-made electrode architectures, such as those with 3D gradients of ion conductors and catalyst particles. These approaches further optimise state-of-the-art materials and technologies and lay the foundation for high-performance next-generation MEA components.

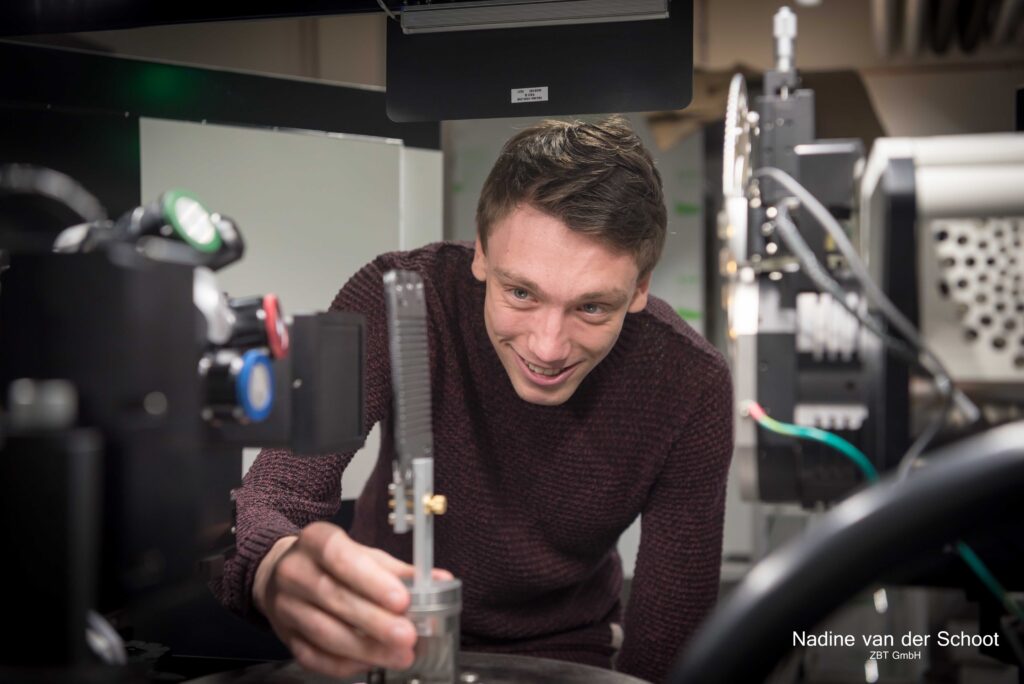

MEA Production Technology and Characterisation

The MPC group is dedicated to application-oriented research for the development and optimisation of manufacturing processes and industry-appropriate production processes for electrochemically active layers, CCMs and MEAs for fuel cells and electrolysis applications. In addition to electrode and MEA design, the focus is on scalable coating processes such as doctor blade and slot die coating. In addition, the group has a wide range of advanced characterisation methods at its disposal for determining key parameters such as the electrical, thermal and proton conductivity, permeability and much more of individual components and MEAs.