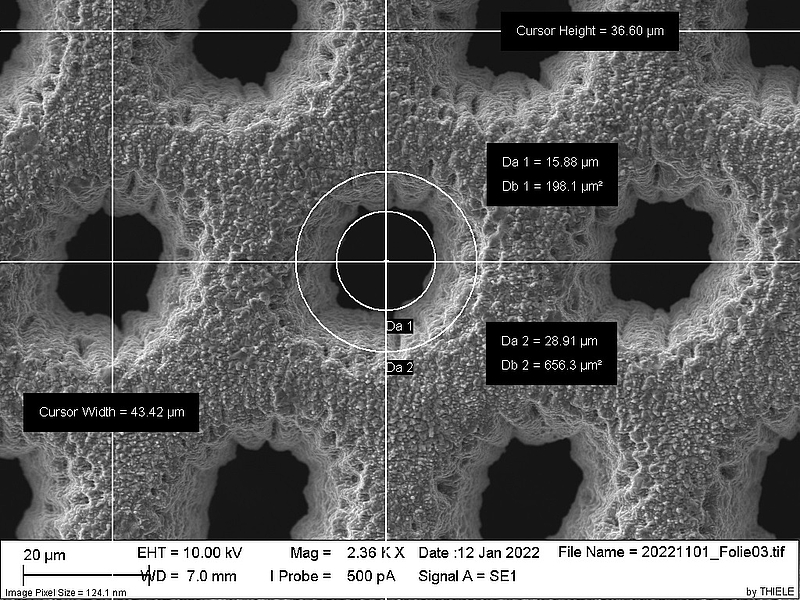

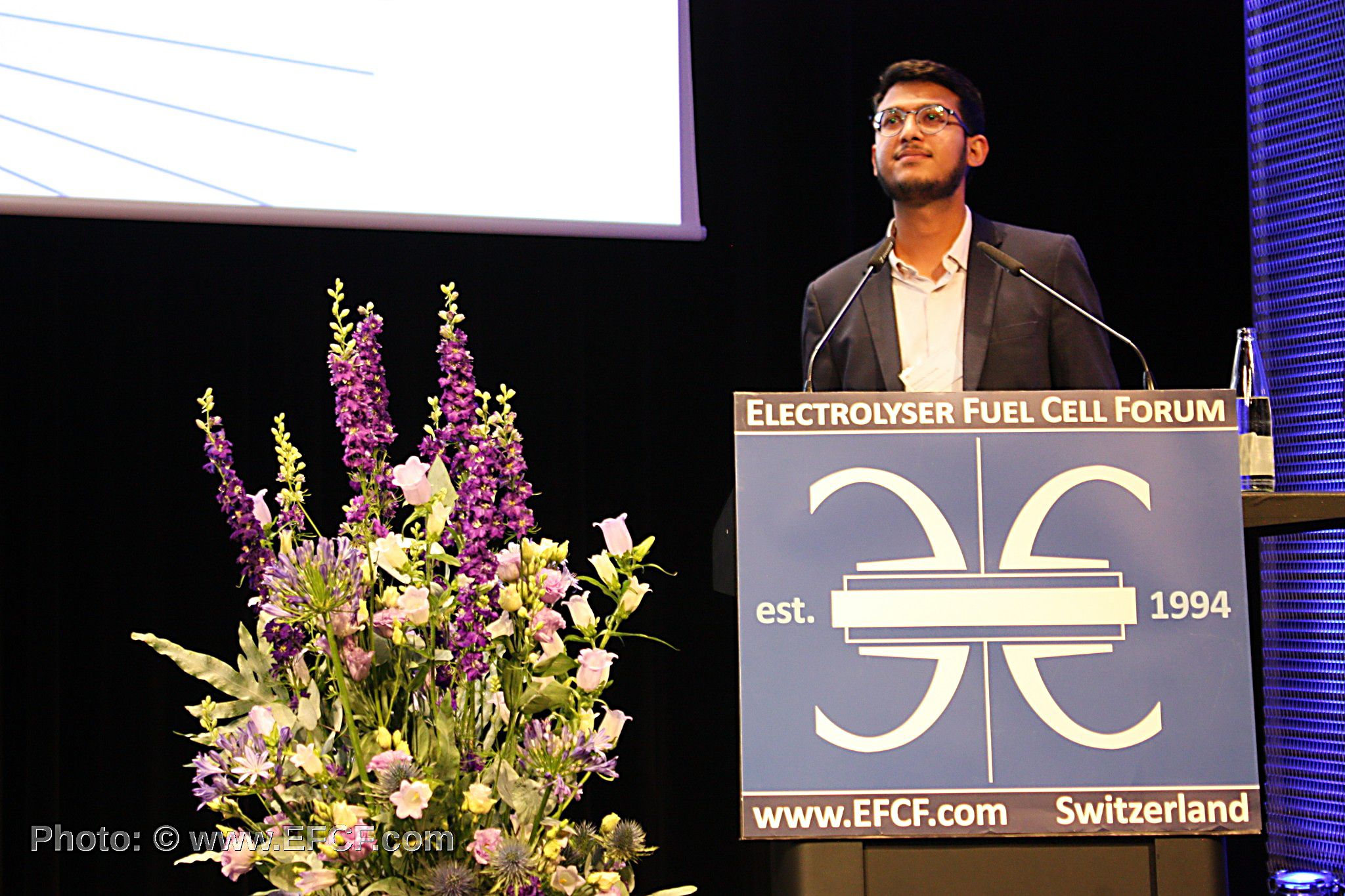

‘Laser-structured titanium foils as PTL in PEM-WE cells and the influence of porosity on mass transport properties on the anode side’

For many of those who followed ZBT scientist Sebastian Hirt’s presentation at the EFCF – European Electrolyser and Fuel Cell Forum, this presentation title will have been perfectly understandable. For everyone else, an explanation may be necessary:

What is a PTL? And what is the significance of the pores in the titanium foil?

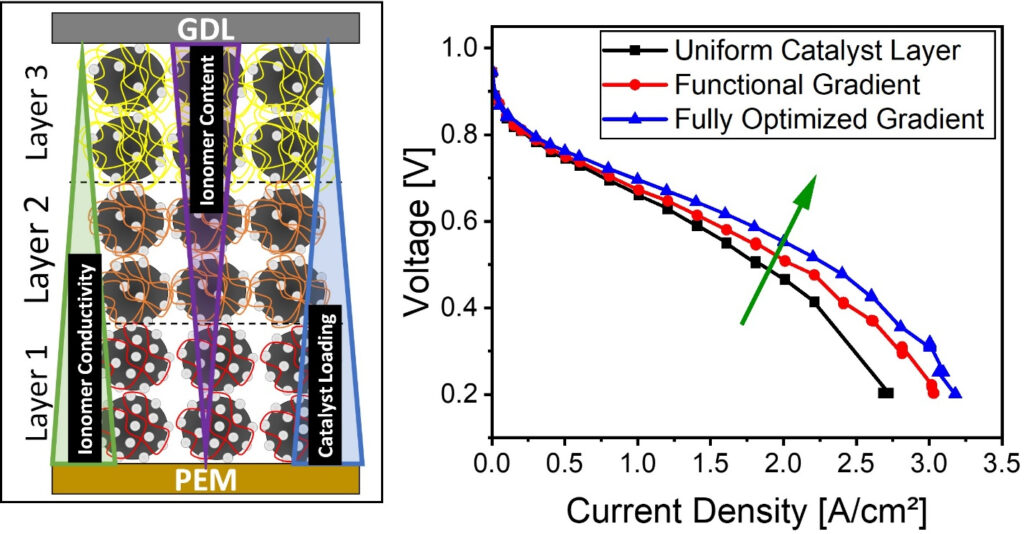

The porous transport layer (PTL) is a central component of electrolysers, especially in proton exchange membrane water electrolysis (PEMWE).

It fulfils three important tasks:

- It transports water to the catalyst layer, where it is separated into protons and oxygen.

- It conducts the resulting gases away.

- It establishes electrical contact between the catalyst and the current collector. This is important because without electricity, there is no hydrogen.

The challenges in PTL development are complex:

- The PTL must be electrically conductive and offer the largest possible contact area with the catalyst layer to enable efficient electron transport.

- At the same time, high porosity is necessary so that water and gases can flow through the layer easily.

- These two requirements often contradict each other and require a sophisticated design.