Stack Technologies

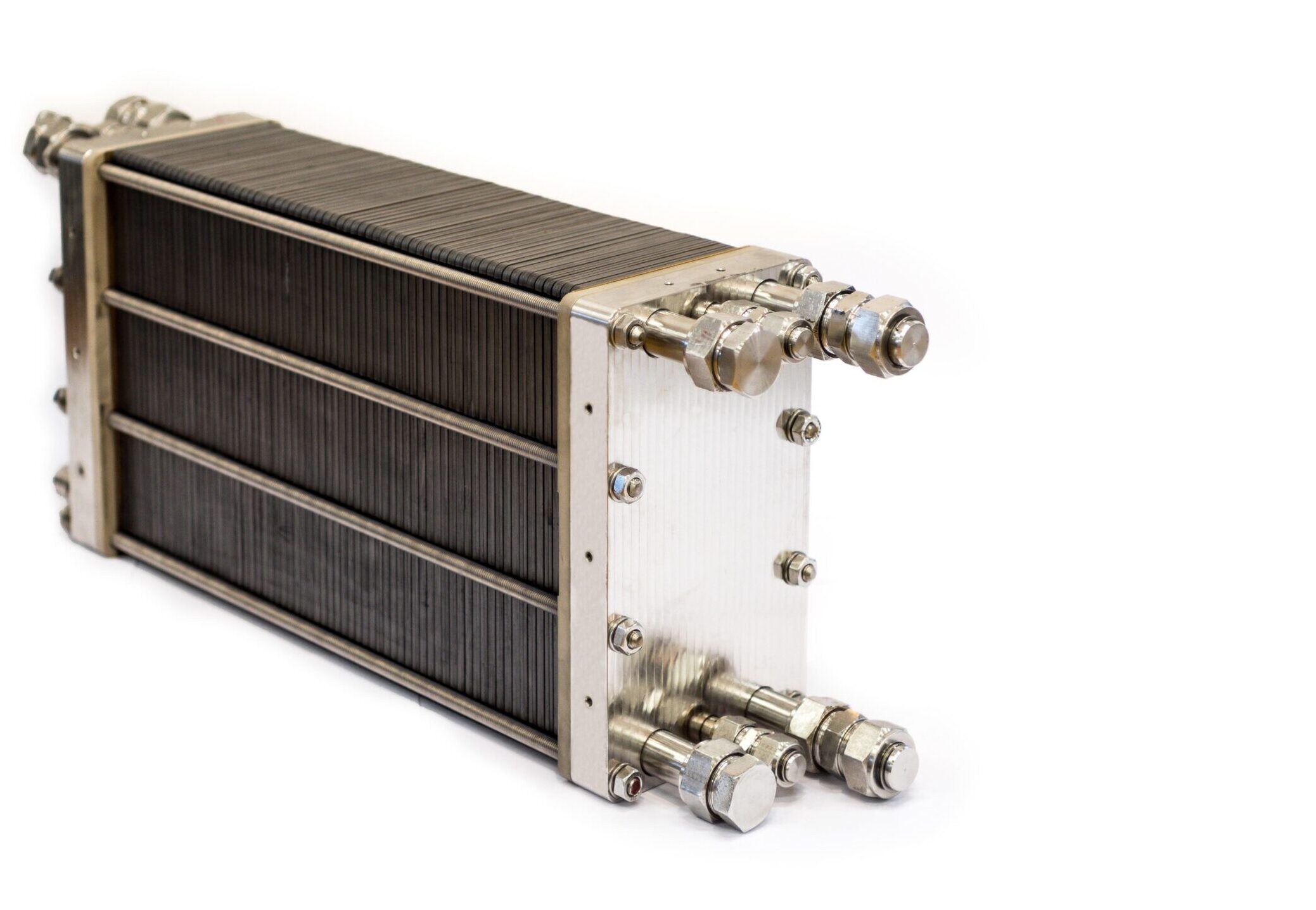

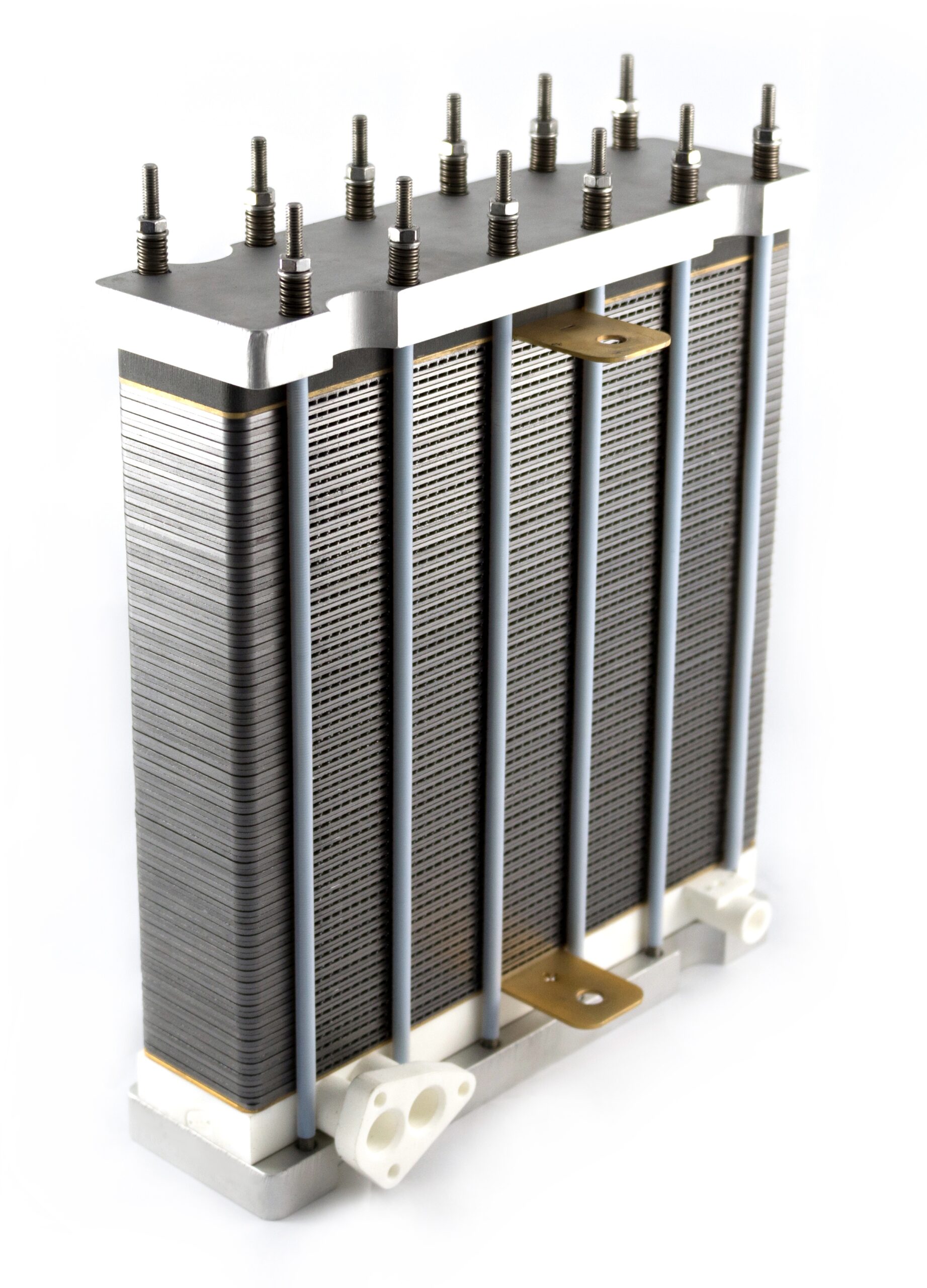

As part of research projects and industrial collaborations, we work with our partners to develop high-performance fuel cell stacks for mobile, stationary and portable applications.

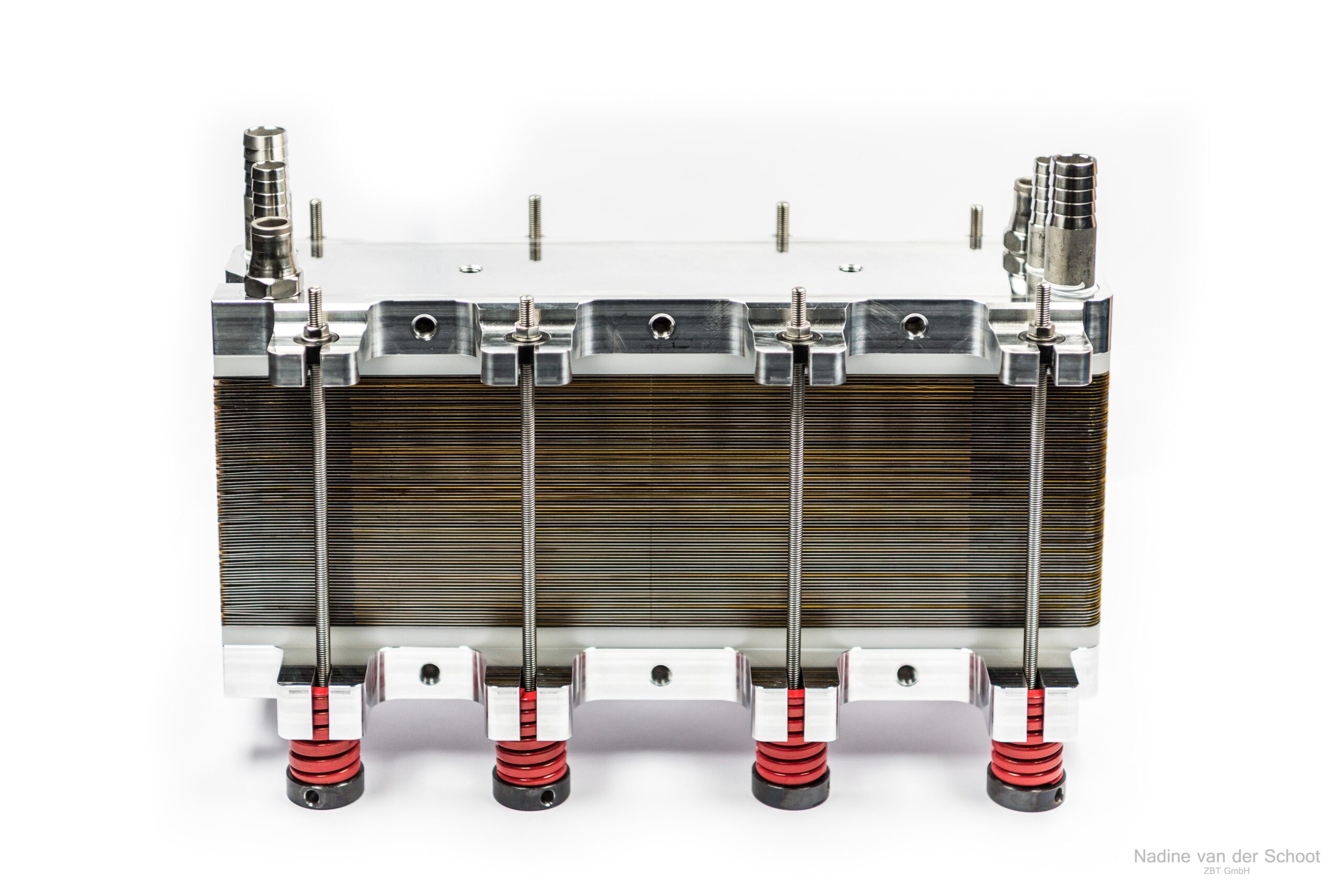

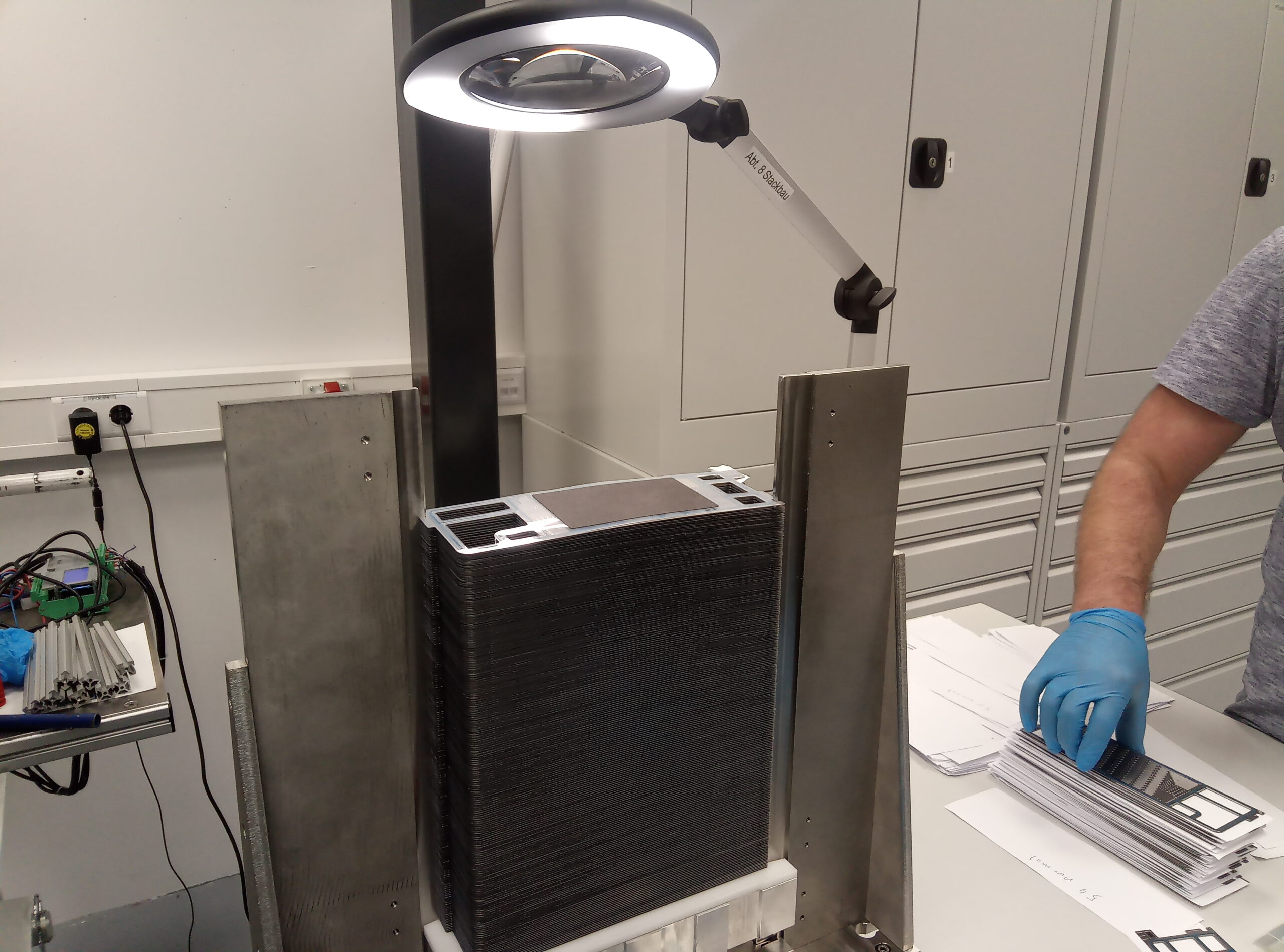

We develop optimised clamping systems for fuel cells and research production-optimised fuel cell stack designs and automated assembly processes.

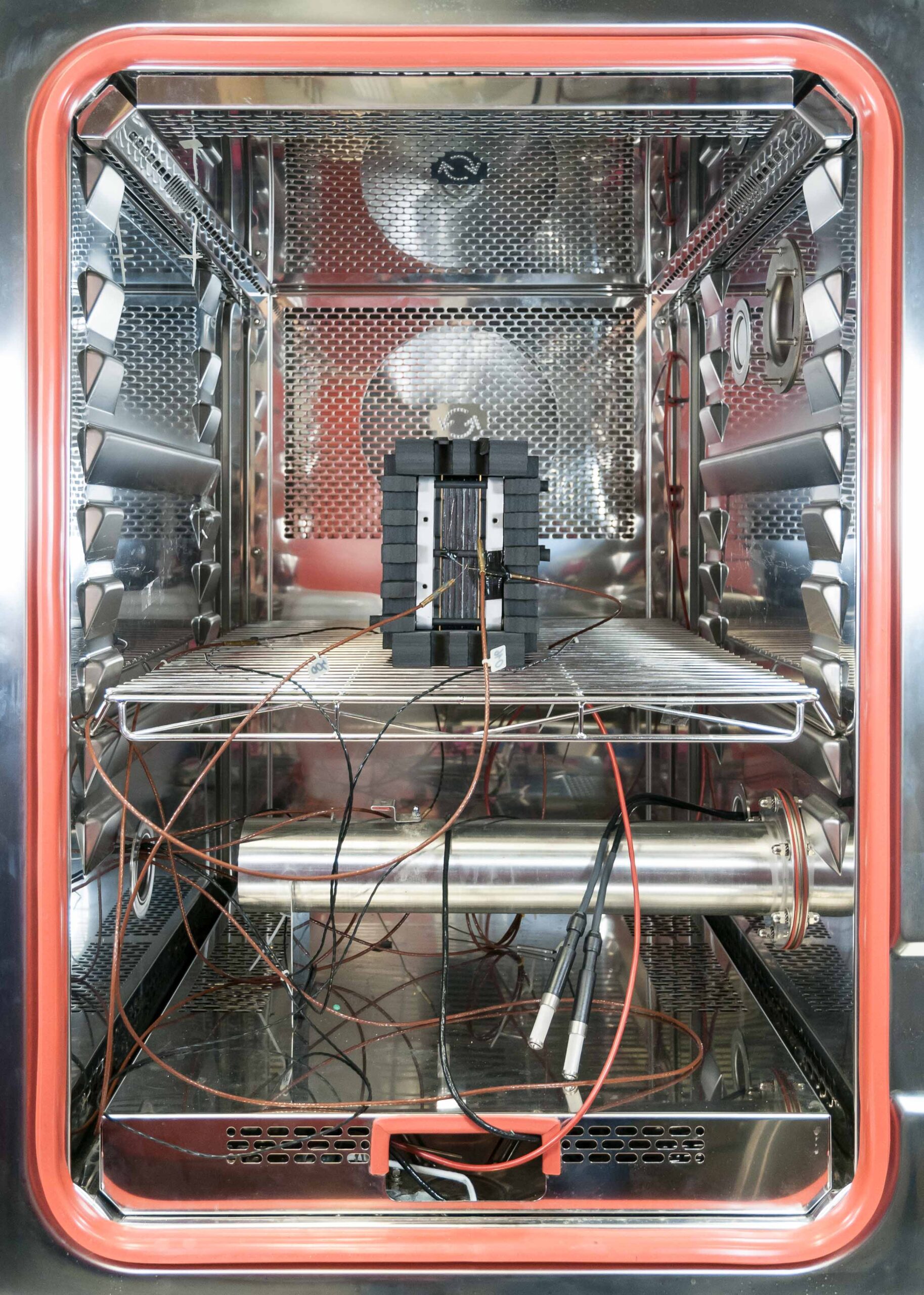

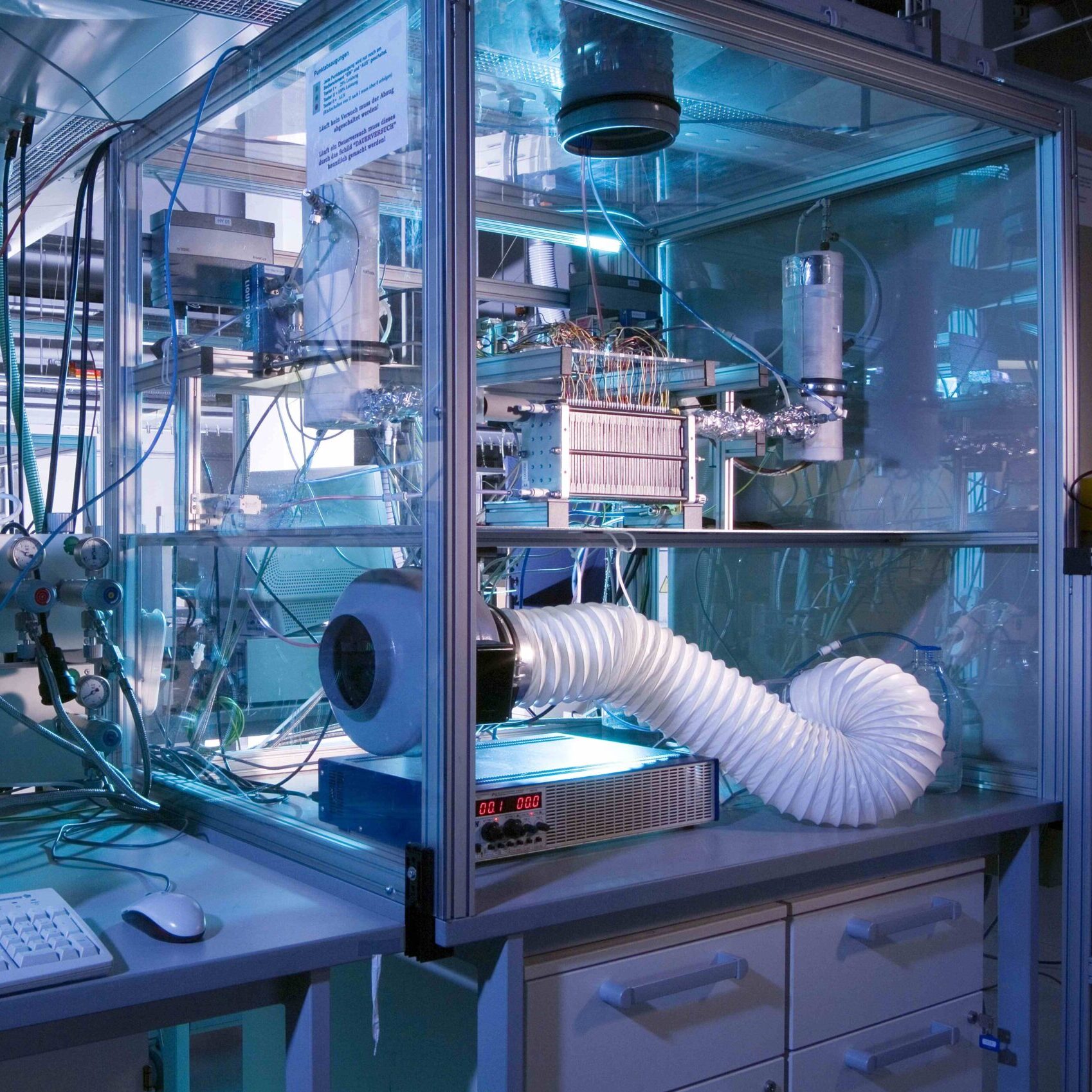

We characterise and qualify single cells, multi-cells and entire fuel cell stacks on numerous test benches.

Contact for Stack Technologies

Head of Department Fuel Cell and Stack

Dr. Jörg Karstedt

+49 203 7598-1178