Membrane Electrode Assemblies

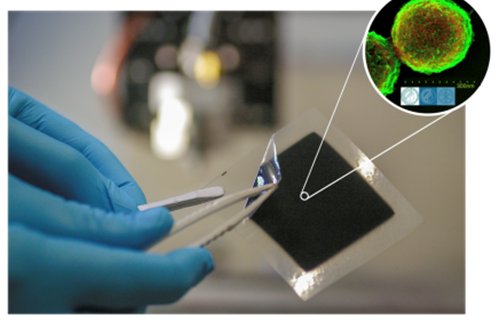

The membrane electrode assembly (MEA) forms the heart of both polymer electrolyte membrane fuel cells (PEMFC) and PEM electrolysers. In fuel cells, it is where chemical energy is converted into electrical energy, while in electrolysers, electrical energy is used to split water into hydrogen and oxygen.

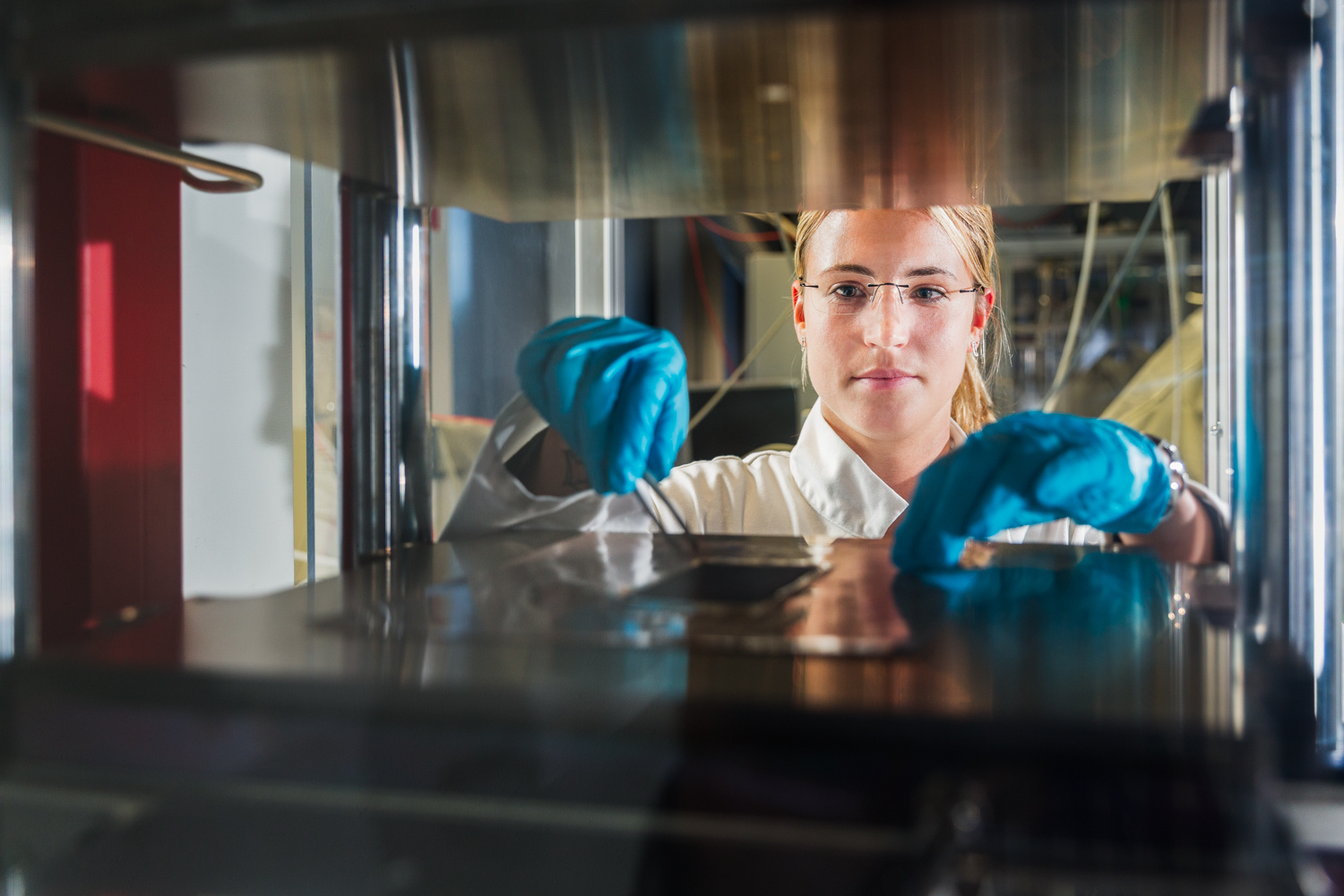

In order to make this conversion or power generation process as efficient and stable as possible, targeted research is needed on the individual components and composite structures, taking into account the interactions between them. In particular, the production and transfer of catalyst layers onto the membrane involves a large number of possible manufacturing steps, each of which has its own parameter matrix. We value scalability from laboratory scale to roll-to-roll production and therefore take cost-efficient manufacturing strategies into account right from the start.