New Materials and Technologies Department

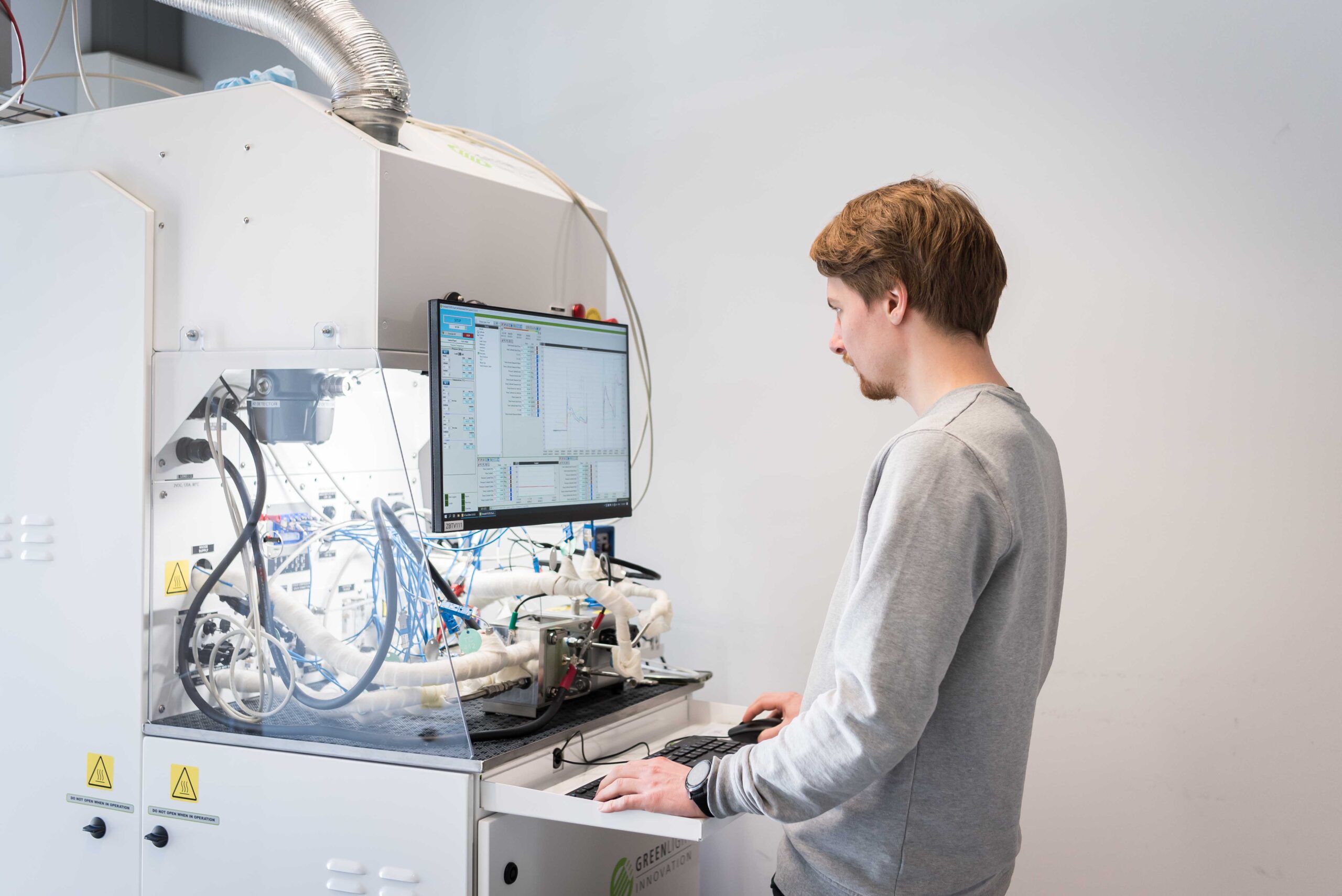

The department’s core task is to develop inventions in the field of hydrogen and fuel cell technology and systematically transfer them into application-oriented research. This includes the analysis and development of new materials and processes.

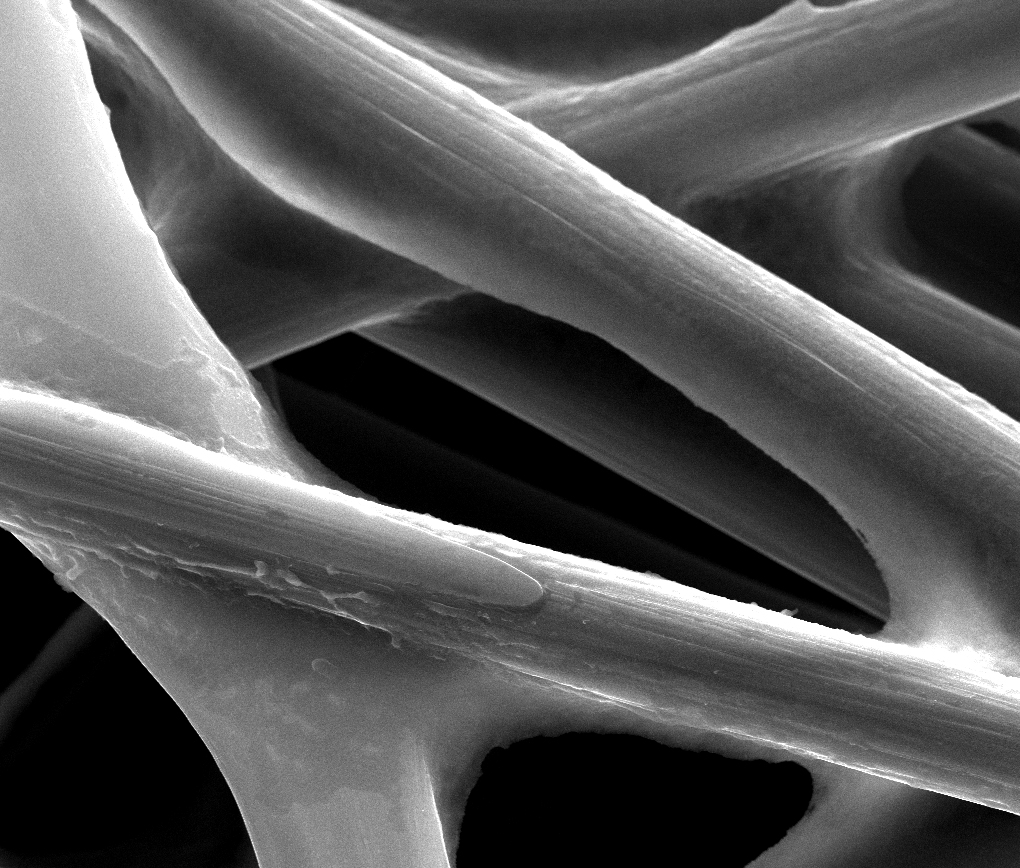

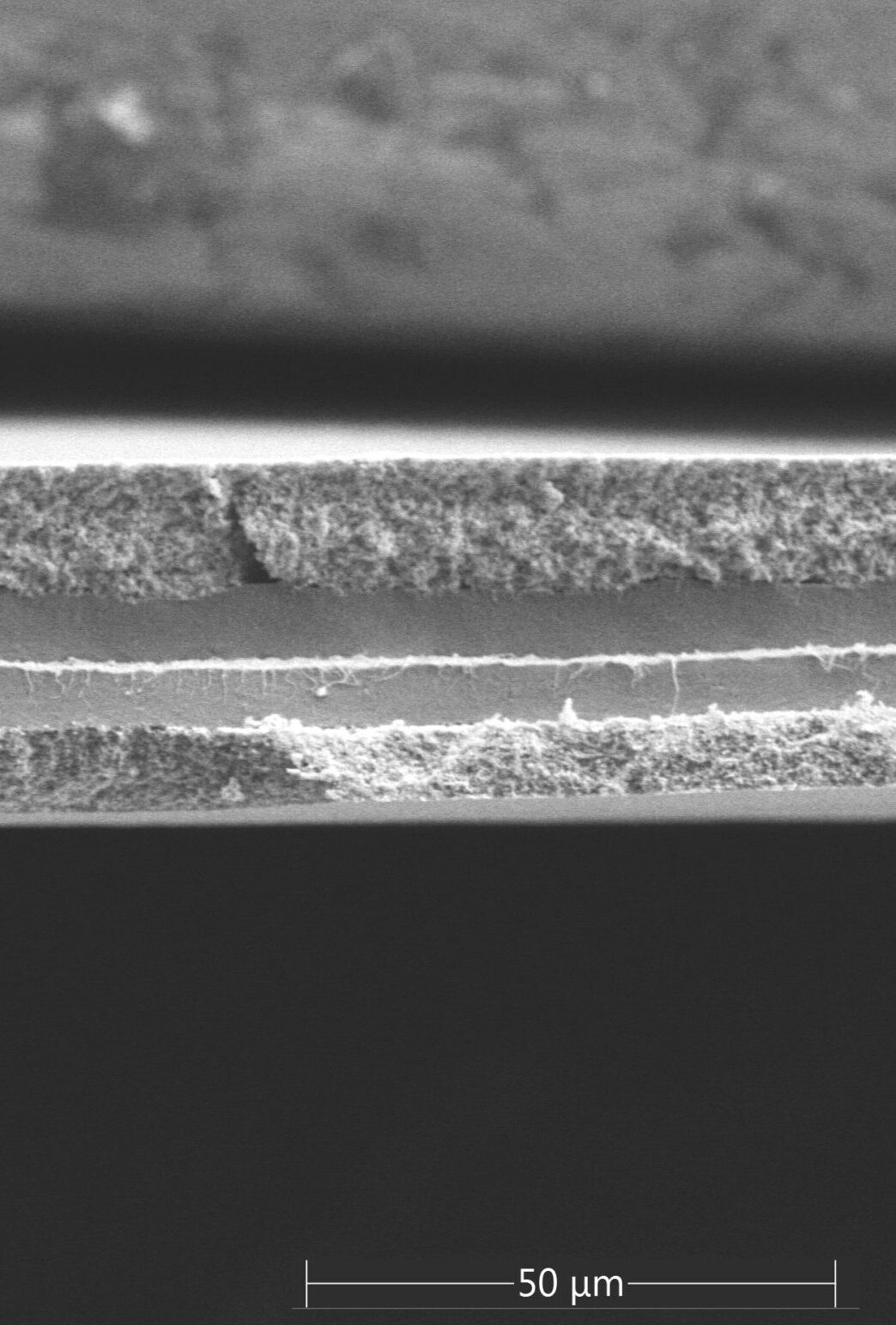

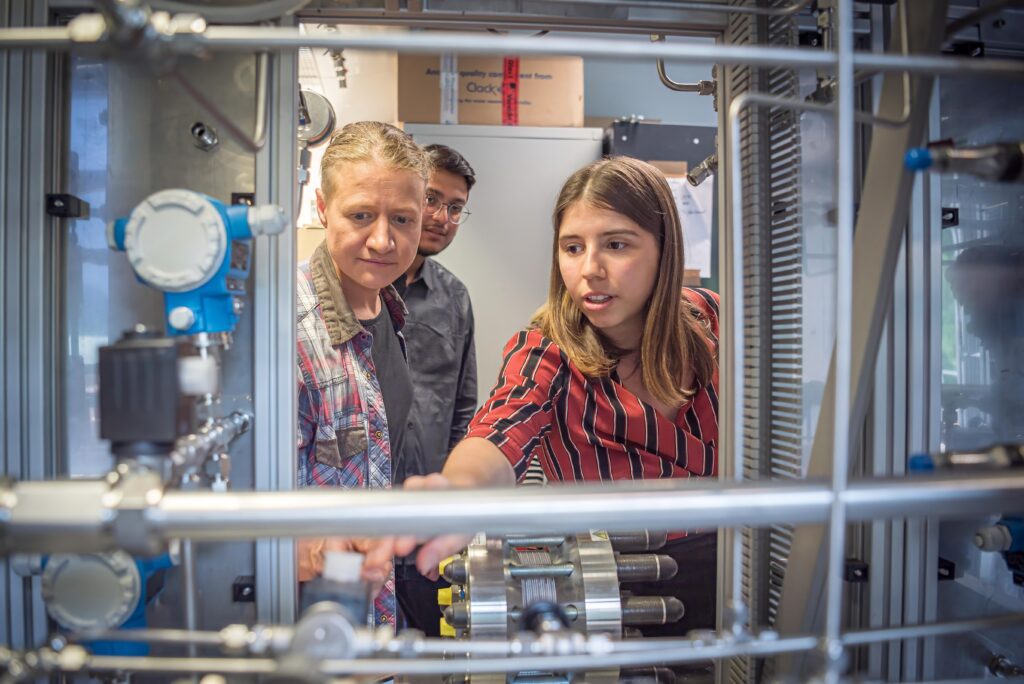

The New Materials and Technologies department links basic research and industrial applications. The focus is on the development and characterisation of new materials for hydrogen and fuel cell technology and the optimisation of measurement methods and innovative processes. The materials and technologies can be used in a wide range of applications, from small portable fuel cell systems to future-oriented applications in shipping and aviation.

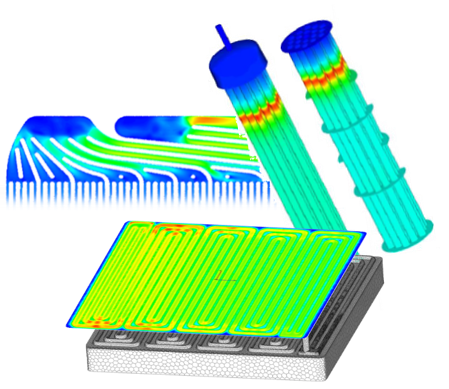

New methodological skills are acquired with the help of standardisation measures. Product and process optimisation and the development of test concepts for different types of fuel cells and electrolysers (NT-PEM, HT-PEM, NT-AEM) are also the focus of the work. Transport and reaction mechanisms in individual materials, components or entire systems are investigated using various modelling and simulation methods in addition to experimental characterisation.

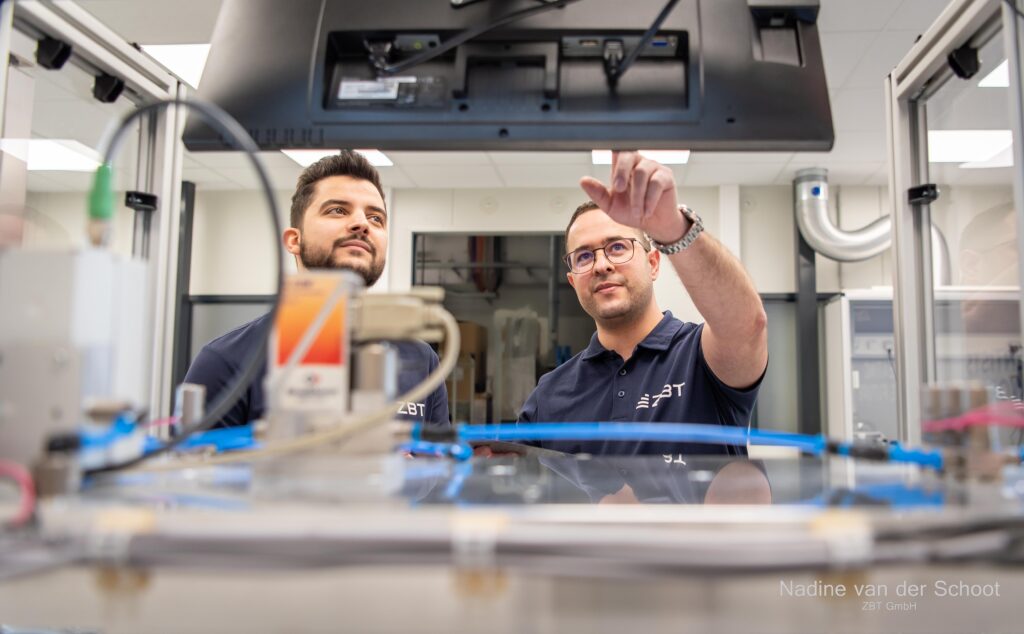

In addition to material and technology developments, the three working groups ‘Material Analysis and Quality Assurance’, ‘Modelling and Simulation’ and ‘AEM Electrolysis and Fuel Cells’ carry out simulative investigations into fluid engineering and multiphysical issues in process engineering components.