Modelling & Simulation

Would you like to better understand, develop or optimise complex hydrogen systems?

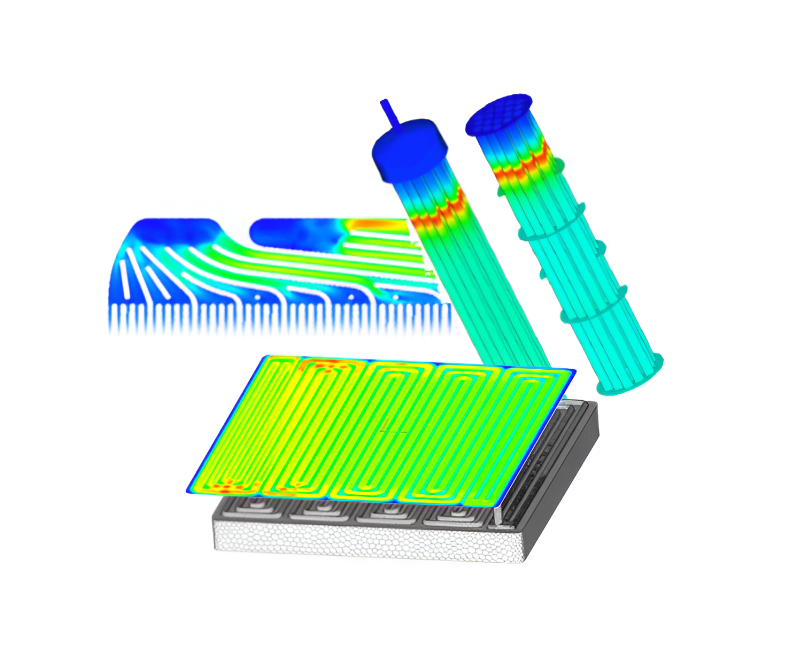

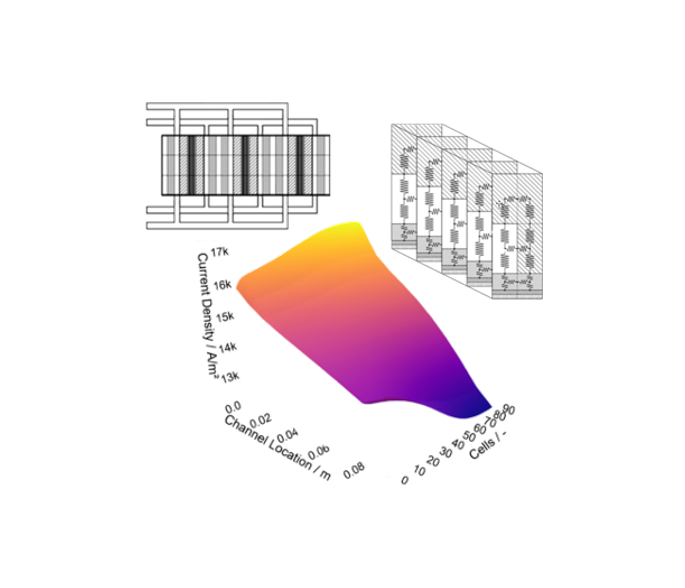

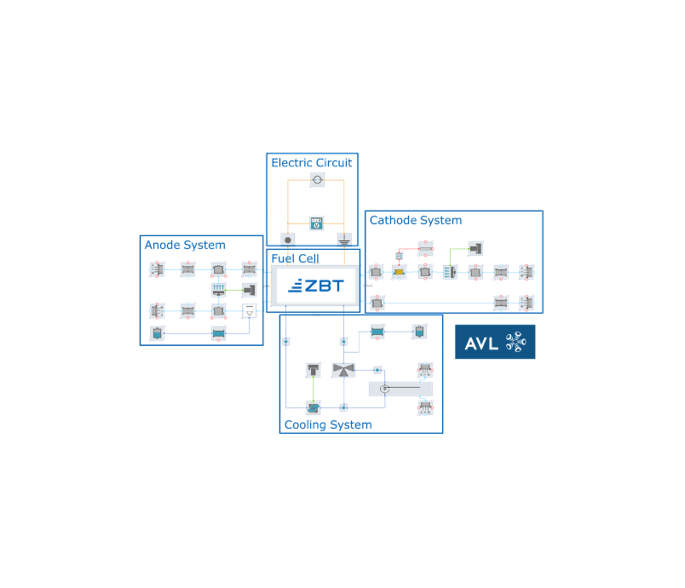

Using physically based models and simulation-based approaches, we analyse transport and reaction processes along the hydrogen value chain – from porous materials to cells to entire plants. Our models help to understand systems, identify weak points and efficiently develop new solutions.